Experts in AI-powered 3D Simulations and Real-Time Visualization Technologies.

Unlock new possibilities in product development, process optimization, and facility planning with our expertise in AI-powered 3D simulations and real-time visualizations.

- Complete Service: We accompany you from the idea generation to implementation. Employ advanced 3D models for efficient product development and manufacturing simulations.

- Custom Solutions: Our technology is flexible and applicable across industries. From detailed logistics simulations to optimizing factory layouts – we support your specific needs.

- Technological Edge: Benefit from the advantages of advanced AI-powered 3D simulations for precise planning and optimization of your processes and facilities.

Leverage our comprehensive expertise for innovative, efficient, and interactive solutions in your business areas.

The Expertise of Visoric in AI-powered 3D Simulations

The Power of AI-driven 3D Simulations:

Discover how our AI-driven 3D simulation frameworks enable cross-industry innovations. From developing interactive learning software for mixed reality applications to powerful tools for AR headsets – we offer tailored solutions that support and advance your business goals.

Customized to Your Needs:

Our AI-driven 3D simulations are individually adapted to your industry and specific requirements. Whether for impressive presentations in virtual showrooms, creating realistic animations, or for data-based customer analysis in VR marketing apps – we open new dimensions for your business.

Benefits for Your Business:

With AI-powered 3D simulations, we take your business to the next level. You benefit from improved interaction possibilities, more efficient planning processes, and innovative solutions that create a sustainable and future-oriented digital world. Use these technologies to gain competitive advantages and strengthen your market presence.

Ready for digital transformation? Contact us for a tailored consultation and discover how we can transform your business.

How Your Business Benefits from Our AI-powered 3D Simulation Innovations

Cost Efficiency through Automation: Our AI-powered 3D simulation solutions automate and optimize complex processes in product development, manufacturing, and facility planning, leading to significant cost savings.

Faster Decision Making: By simulating realistic manufacturing and logistics processes, our solutions enable real-time analyses and accelerate data-driven decisions.

Increased Efficiency and Customer Satisfaction: Improved planning and design through 3D simulations not only enhance efficiency but also the satisfaction and loyalty of your customers.

Risk Reduction: Our 3D simulation solutions minimize errors and increase safety in critical areas such as medicine, architecture, and industry, thereby reducing liability risks.

How to Reach Us!

Email: info@visoric.com

Phone: +49 89 21552678

Contact Person:

Ulrich Buckenlei (Creative Director)

Mobile +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile + 49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich

Questions about AI-powered 3D Simulations?

If you would like to learn more about the diverse applications and benefits of our AI-powered 3D simulation technologies, we are at your disposal. Do not hesitate to contact us! We look forward to your inquiry.

Where are AI-powered 3D Simulations Used in Business?

Virtual Commissioning as an Application Field of AI-powered 3D Simulation

Application Areas:

- Software Development: Decoupling of software development from upstream and downstream processes like mechanics and electrics.

- Error Detection: Early identification and optimization of potential errors before the real system is manufactured.

- Programming Work: Shifting programming work from the construction site to the office.

- Reduction of Commissioning Crashes: Minimizing commissioning crashes through the model-based approach of the digital twin.

- Stable Production Processes: Ensuring high technical availability of machines through mature automation software.

Benefits:

- Time-Critical Projects: Enables efficient implementation of complex projects, especially during modifications.

- Risk Reduction in Project Management: Better progress tracking for more efficient project execution.

- Cost and Time Savings: Shortening the on-site commissioning leads to lower travel expenses and more efficient project implementation.

- Quality Improvement: Increasing the quality of the delivered system through comprehensive virtual testing and optimizations.

- Training and Education: Effective training of employees and process partners in the functionality of the system.

AI-powered 3D Simulation in Product Development and Design

Application Areas:

- Prototype Development: Creation and testing of virtual prototypes, reducing the need for physical models.

- Design Optimization: Use of AI-powered analysis tools to improve design aspects, based on performance data and user feedback.

- Material and Component Testing: Simulation of various materials and components under real conditions to check durability and functionality.

Benefits:

- Efficiency Increase: Acceleration of the design process through rapid iteration and testing of concepts in a virtual environment.

- Cost Reduction: Reduction in costs for creating physical prototypes and associated testing procedures.

- Time to Market: Speeding up the time to market by early identification and rectification of design issues.

AI-powered 3D Simulation in Manufacturing and Process Simulation

Application Areas:

- Production Process Optimization: Analysis and simulation of manufacturing processes to increase efficiency and minimize errors.

- Capacity Planning: Modeling and assessment of different production capacities and scenarios for optimal resource utilization.

- Workplace Design: Ergonomic and efficient design of workplaces and production lines through virtual simulation.

Benefits:

- Productivity Increase: Identification and implementation of more efficient production methods through precise simulations.

- Reduction of Downtimes: Early detection and resolution of bottlenecks and potential disruptions in the manufacturing process.

- Improved Work Safety: Simulation of workflows to identify and minimize safety risks.

AI-powered 3D Simulation in Facility and Factory Planning

Application Areas:

- Layout Optimization: Design and visualization of facility layouts to achieve optimal space utilization and workflow efficiency.

- Simulation-based Planning: Conducting simulations to predict and analyze production behavior under various conditions.

- Safety and Evacuation Analysis: Use of 3D models to assess and improve safety protocols and evacuation routes.

Benefits:

- More Efficient Planning Processes: Acceleration and improvement of planning quality through detailed, realistic simulations.

- Cost Reduction: Early identification of planning errors that could be costly in real implementation.

- Increased Safety: Optimization of facility safety and work environment through simulated scenarios and analyses.

AI-powered 3D Simulation in Logistics and Supply Chain Management

Application Areas:

- Warehouse Layout and Optimization: Simulation and design of efficient warehouse layouts to maximize storage capacity and optimize the flow of goods.

- Transport Route Planning: Analysis and optimization of transport routes and methods to reduce delivery times and costs.

- Inventory and Demand Analysis: Forecasting and management of inventories through simulated scenarios for demand prediction.

Benefits:

- Improved Efficiency: Increase in overall efficiency in the logistics chain through optimized processes and resource utilization.

- Cost Savings: Reduction of logistics costs through optimized inventory management and transport planning.

- Increased Flexibility: Quick adaptation to market changes and demand fluctuations through precise, data-driven simulations.

Potential of AI-powered 3D Simulations in Core Areas:

- Product Development and Design: Accelerates and optimizes the design process through virtual prototypes and design simulations.

- Manufacturing and Process Simulation: Enables precise planning and analysis of manufacturing processes and workflows for efficiency improvement.

- Facility and Factory Planning: Supports detailed planning and optimization of factory layouts and facilities considering safety and efficiency.

- Logistics and Supply Chain Management: Provides advanced solutions for optimizing inventory, transport routes, and inventory management.

Additional Benefits:

- Overall Efficiency Increase: Enhances productivity and reduces costs through optimized processes and procedures.

- Risk Minimization and Quality Assurance: Enables precise predictions and analyses to reduce errors and improve quality in all business areas.

Explore Selected Examples of Our AI-powered 3D Simulations

For more than 14 years, our fascination and enthusiasm have been dedicated to developing high-performance, exceptionally realistic AI-powered 3D simulations. We are excited to enter new levels of interactive and immersive user experience with you. Let’s create something extraordinary together.

Virtual Commissioning – Best Practices

Use of AI-powered 3D Simulation in the Machinery and Plant Industry

This model demonstrates the innovative use of AI-powered 3D simulations in the virtual commissioning of machinery and plants.

Implementation and Benefits:

Our AI-powered 3D simulation technology enables comprehensive virtual commissioning of machines and plants long before physical assembly begins. This leads to a significant reduction in errors and downtime during the actual commissioning phase.

Optimization of Development Processes:

Early identification and resolution of issues in the virtual environment shorten development cycles and enhance the quality of final products. The technology offers the ability to test and optimize complex systems in a safe and cost-efficient virtual environment.

Successes and Savings:

The use of AI-powered 3D simulations in virtual commissioning has led to significant time and cost reductions in various projects. Companies have been able to accelerate the market launch of their products while simultaneously increasing the quality and reliability of their plants.

Additional Benefits:

This technology also enables effective training and onboarding of operating personnel before the physical plant exists, further increasing efficiency.

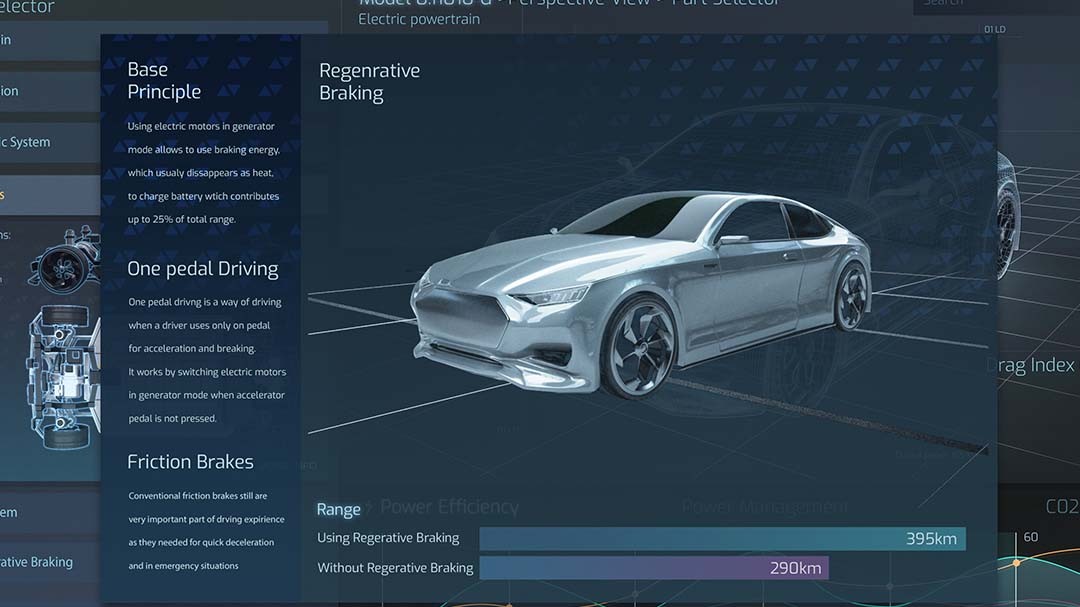

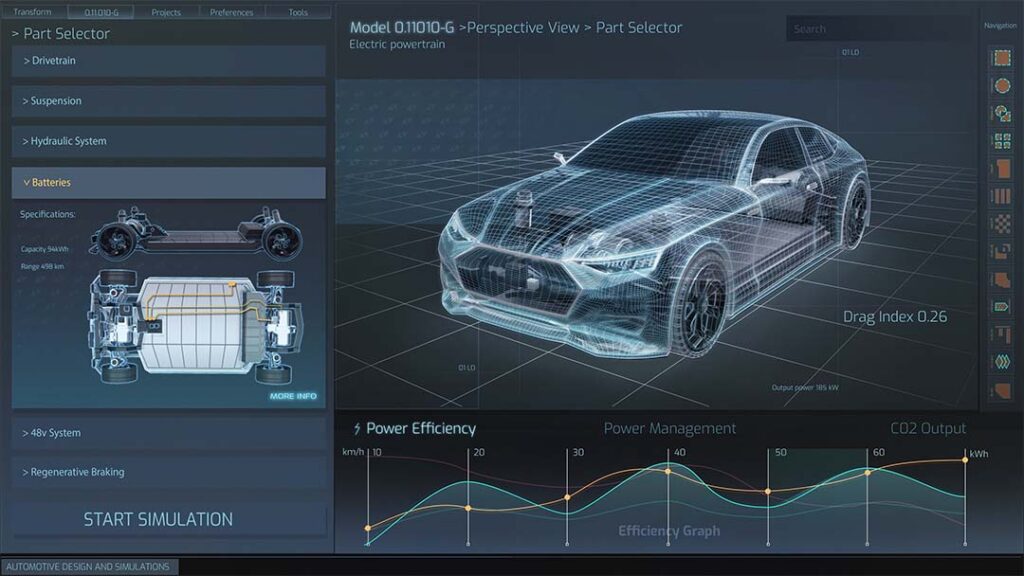

Product Development and Design – Best Practices

Innovative Application of AI-powered 3D Simulation in Product Design

This example shows how AI-powered 3D simulations revolutionize the design process in product development.

Implementation and Innovation:

Our AI-powered 3D simulation technology enables designers to develop and test complex product models virtually. This leads to faster iteration and refinement of design concepts without relying on physical prototypes.

Design Optimization and Cost Efficiency:

The use of 3D simulations allows for efficient evaluation and optimization of various design variations. This reduces the costs and time typically needed for creating and testing physical prototypes.

Successes and Market Advantages:

The application of AI-powered 3D simulations in product development has led to a significant acceleration of the design process and reduction in development times in several projects. Companies have been able to bring their products to market faster, thereby securing a competitive edge.

Additional Benefits:

The technology not only enables more efficient product development but also improves the accuracy and quality of final products by providing comprehensive testing and analyses in a virtual environment.

Manufacturing and Process Simulation – Best Practices

Enhancing Efficiency in Manufacturing through AI-powered 3D Simulation

This example illustrates the successful use of AI-powered 3D simulation to optimize manufacturing processes.

Implementation and Process Improvement:

Our advanced 3D simulation technologies enable detailed analysis and optimization of manufacturing processes. This allows companies to identify bottlenecks, streamline workflows, and increase overall productivity.

Cost Reduction and Quality Enhancement:

Precise simulation of manufacturing processes allows for early detection and rectification of error sources. This leads to a significant reduction in waste and rework, enhancing product quality and lowering costs.

Successes and Competitive Advantages:

Companies using AI-powered 3D simulations in their manufacturing processes report significant improvements in efficiency and quality. The technology enables them to respond more quickly to market changes and strengthen their competitive position.

Additional Benefits:

In addition to process optimization, these simulations also contribute to improved workplace safety by virtually simulating dangerous scenarios and allowing for risk mitigation measures.

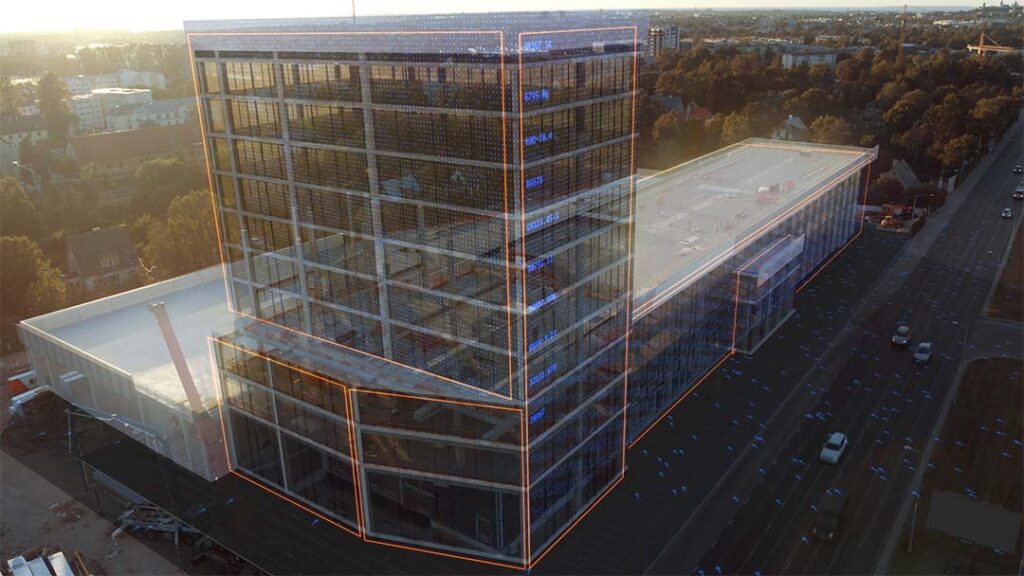

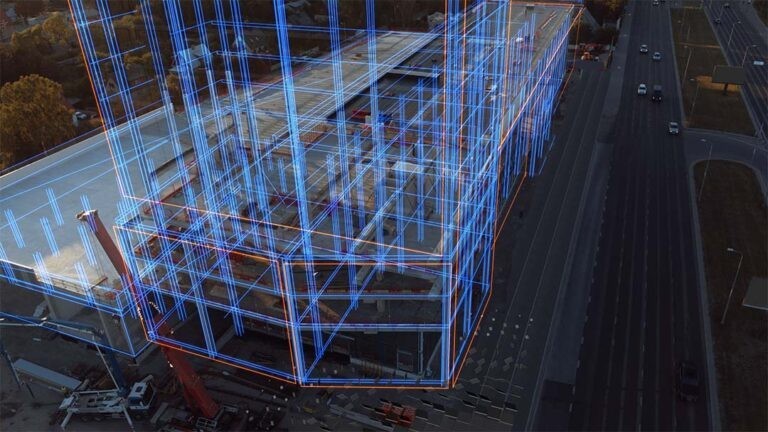

Facility and Factory Planning – Best Practices

Revolutionizing Facility and Factory Planning with AI-powered 3D Simulation

This example demonstrates how AI-powered 3D simulations contribute to the optimization of facility and factory layouts.

Implementation and Efficiency Enhancement:

With our AI-powered 3D simulation technology, companies can virtually design and analyze complex factory layouts. This enables optimal space utilization and process design before the first ground-breaking.

Cost Reduction and Time Savings:

Early identification and resolution of planning issues in a virtual environment can significantly lower construction and operational costs. At the same time, planning and construction time are reduced.

Successes and Sustainable Development:

Companies using AI-powered 3D simulations in the planning phase report a significant reduction in errors and rework during construction. This leads to faster completion and more sustainable operations.

Additional Benefits:

These technologies not only support more efficient planning but also improve safety and ergonomics in the workplace by highlighting potential risks and opportunities for improvement.

Logistics and Supply Chain Management – Best Practices

Optimizing Logistics Processes with AI-powered 3D Simulation

This example shows how AI-powered 3D simulations enhance efficiency in logistics and supply chain management.

Implementation and Process Improvement:

Our advanced 3D simulation technologies enable detailed visualization and analysis of logistics processes. This helps companies to design optimal warehouse layouts and plan efficient transportation routes.

Cost and Time Savings:

By simulating various logistics and supply chain scenarios, companies can identify the best strategy for inventory management and distribution, leading to significant cost savings.

Successes and Competitive Advantages:

Companies using AI-powered 3D simulations in their logistics and supply chain management report improved inventory control, faster delivery times, and increased overall customer satisfaction.

Additional Benefits:

The technology not only contributes to the optimization of logistics processes but also enhances planning security and flexibility in the supply chain, enabling companies to better respond to market fluctuations.

Risk Management and Emergency Planning – Best Practices

Enhancing Safety through AI-powered 3D Simulation

This example shows how AI-powered 3D simulations can be used in risk management and emergency planning.

Implementation and Safety Improvement:

With our AI-powered 3D simulations, companies can identify potential risks in their operational processes and develop effective emergency plans. The simulations allow for playing out various crisis scenarios and determining the best course of action.

Prevention and Crisis Response:

The 3D simulations aid in developing strategies for risk reduction and enable quick and informed responses in crisis situations. This contributes significantly to the safety and resilience of the company.

Successes and Operational Continuity:

Companies using AI-powered 3D simulations for risk management and emergency planning benefit from improved operational continuity and a reduction in downtime and damage in case of emergencies.

Additional Benefits:

In addition to enhancing safety, these simulations also provide valuable insights for training employees in emergency procedures, further reducing the overall risk for the company.

How to GO NEXT.

We are Your Reliable Partner for AI-powered 3D Simulation Solutions for Businesses.

- Consultation: We analyze your requirements in the area of AI-powered 3D simulations and offer comprehensive consulting.

- Implementation: We develop customized 3D simulation solutions specifically tailored to the needs of your business.

- Support: We provide continuous support and updates to ensure that your AI and simulation systems remain efficient and up-to-date.

Leverage the possibilities of AI-powered 3D simulations to fully realize the potential of your business.

What You Can Expect from an AI-powered 3D Simulation Demo:

Concrete Examples: Experience how AI-powered 3D simulations can transform your business in real-world use cases.

Interactive Experience: Learn more about the benefits of AI-powered 3D simulations and how this technology can be integrated into your business.

Individual Consulting: Our experts are available to discuss your individual requirements in the field of AI-powered 3D simulations and provide tailored solutions.

FAQ about AI-powered 3D Simulation

What services does Visoric offer to corporate clients in the field of 3D simulation?

Visoric offers a wide range of services to its corporate clients in the field of 3D simulation, such as:

- the concept and prototype development of 3D simulations of all kinds

- Development and verification of tool-chains and system designs

- AI-powered product configurations

- Real-time 3D simulations in Extended Reality (XR simulations)

- Real-time 3D simulations in Virtual Reality (VR simulations)

- Real-time 3D simulations in Augmented Reality (AR simulations)

- Simulations of virtual factories and virtual production facilities in the Industrial Metaverse in real-time

- Design, procurement, and custom fabrication of hardware for real-time 3D simulations such as VR and AR glasses, cockpits, seat boxes, balance boards, etc.

- Programming of individual hardware interfaces, e.g., CAN bus controls via Raspberry Pi

Our goal is to provide our customers with the ability to develop their products faster and more securely and to achieve the best possible results.

Can I also experience my simulation in VR?

Yes, that is no problem.

We offer our clients the opportunity to experience their simulations in VR.

This allows for an even more realistic and immersive experience, helping to better understand and tailor the products."

What is the advantage of AI-powered 3D simulations?

AI-powered 3D simulations enable us to perform tests more quickly and safely and to accelerate product maturity.

They also allow for the individual configuration of products based on customer desires and provide visualizations for Google queries about components, even if the product does not exist at the time of the query.

Can you provide me with an example of a project in the field of AI-powered 3D simulation in VR space that Visoric was involved in

One of our recent projects was the development of a VR driving simulator with AI for BMW AG.

The simulator enables the implementation of flexible vehicle scenarios using an editor and testing scenario-dependent AR objects on the head-up display in the vehicle or optionally in AR headsets/glasses such as the Microsoft HoloLens.

The 3D simulator we co-developed allows BMW to accelerate the prototyping process and advance the development of innovative driving experiences.

What role do the technologies of Virtual Reality, Augmented Reality, and Mixed Reality play in the field of AI-powered 3D simulations?

Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR) play an important role in the field of AI-powered 3D simulations. VR allows users to fully immerse themselves in a virtual world, while AR and MR augment the real world with virtual elements.

Examples of the application of VR in AI-powered simulations:

- Use of VR headsets for training medical staff: In this case, the AI-powered simulation uses VR technology to conduct realistic and interactive training for medical staff. Using VR headsets, medical staff can experience realistic scenarios and practice how they should respond to emergencies or other challenges.

- Use of AR in production to provide employees with real-time information about machines and processes: Here, the AI-powered simulation uses AR technology to provide employees with real-time information. This can include instructions for operating machines, information about processes, or warnings of problems.

- MR is increasingly being used in architecture and real estate to give clients an idea of future construction projects: In this case, the AI-powered simulation uses MR technology to give clients realistic impressions of future construction projects. Using MR headsets, clients can experience interactive and realistic visions of future buildings before they are built.

Visoric is a company that specializes in the development of AI-powered 3D VR and 3D AR applications in the field of complex simulations.

With Visoric, you will be able to utilize the advantages of Artificial Intelligence combined with VR, AR, and MR technology in your company to increase productivity, conduct more effective training, and gain a better understanding of your products and processes. Leverage the possibilities offered by Visoric and revolutionize your business.

Why do specialists in the industrial use of immersive real-time 3D technologies, such as Visoric, engage with Artificial Intelligence?

Specialists in the industrial use of immersive real-time 3D technologies like Visoric engage with Artificial Intelligence (AI) because this technology enables the enhancement of performance and benefits of immersive real-time 3D applications. Some reasons for this include:

Automation: AI technologies such as machine learning and neural networks can be used to automate processes and make decisions that would otherwise need to be made by humans.

Optimization: AI technologies can be used to optimize processes and improve the performance of equipment and machinery.

Personalization: AI technologies can be used to tailor immersive real-time 3D applications to the needs and requirements of users.

Pattern Recognition: AI technologies can be used to recognize patterns in data necessary for making predictions and forecasts.

Therefore, specialists in the industrial use of immersive real-time 3D technologies like Visoric engage with AI to increase the performance and benefits of immersive real-time 3D applications and improve business outcomes.

How can AI-powered 3D simulations be used in the development of cooling systems for electric vehicles?

AI-powered 3D simulations can be used in various ways in the development of cooling systems for electric vehicles. Some examples include:

Creation of Virtual Prototypes: AI-powered 3D simulations can be used to create virtual prototypes of cooling systems for electric vehicles. This allows for the simulation and evaluation of the cooling system's performance in different environments and operating conditions.

Optimization of Cooling Systems: AI-powered 3D simulations can be used to optimize cooling systems for electric vehicles. This allows for the simulation and optimization of heat transfer and fluid flow in the system, thereby improving the performance of the cooling system.

Testing of Cooling Systems: AI-powered 3D simulations can be used to test the cooling system for electric vehicles. This allows for the simulation and evaluation of the cooling system's performance under various environmental conditions and loads, ensuring that the system meets requirements and operates safely.

Identification of Problems: AI-powered 3D simulations can be used to identify problems in the cooling system for electric vehicles. This allows for the early detection and resolution of potential issues in the system before they lead to failures.

All these applications help improve the efficiency and reliability of cooling systems for electric vehicles, ensuring that the system meets requirements and operates safely.

How can reality be connected with the virtual space for simulation in an AI-powered 3D simulation project?

Eine Möglichkeit, die Realität in einem KI-gestützten 3D-Simulationsprojekt mit dem virtuellen Raum zu verbinden, ist die Verwendung von Hardware wie Virtual-Reality-Headsets, Augmented-Reality-Headsets, Motion-Capture-Systemen, 3D-Tiefensensoren und Kameras.

Einsatzbeispiel: In der Architektur- und Bauindustrie kann ein KI-gestütztes 3D-Simulationsprojekt verwendet werden, um die Planung und Konstruktion von Gebäuden zu unterstützen. Durch die Verwendung von Virtual-Reality-Headsets und 3D-Tiefensensoren kann der Benutzer die geplante Konstruktion in Echtzeit erleben und interaktiv Änderungen vornehmen.

Einsatzbeispiel: In der Automobilindustrie kann ein KI-gestütztes 3D-Simulationsprojekt verwendet werden, um die Entwicklung von Fahrzeugen zu unterstützen. Durch die Verwendung von Motion-Capture-Systemen und Augmented-Reality-Headsets kann der Benutzer die Bewegungen und Gesten einer Person in Echtzeit aufnehmen und in die Simulation übertragen, um die Interaktion des Fahrers mit dem Fahrzeug zu simulieren.

Einsatzbeispiel: In der Medizin kann ein KI-gestütztes 3D-Simulationsprojekt verwendet werden, um die Schulung von Ärzten und Chirurgen zu unterstützen. Durch die Verwendung von Virtual-Reality-Headsets und haptischen Feedback-Systemen kann der Benutzer eine realistische Simulation von medizinischen Eingriffen durchführen und dabei die Interaktion mit virtuellen Instrumenten und Patienten simulieren.

Einsatzbeispiel: In der Produktion kann ein KI-gestütztes 3D-Simulationsprojekt verwendet werden, um die Planung und Optimierung von Produktionsprozessen zu unterstützen. Durch die Verwendung von Augmented-Reality-Headsets und 3D-Tiefensensoren kann der Benutzer die Produktionsumgebung in Echtzeit erleben und interaktiv Änderungen vornehmen, um die Effizienz des Prozesses zu verbessern.

What is the cost of developing an AI-powered 3D simulation?

The development of an AI-powered 3D simulation can be a complex and challenging project. It is important that the requirements of the project are clearly and precisely defined, and that the choice of technologies and the development team is carefully considered. The price for developing an AI-powered 3D simulation varies depending on the scope and requirements of the project.

If you are aiming for a successful development of your AI-powered 3D simulation, I recommend the team at Visoric in Munich. This team has experience in developing AI-powered 3D simulations and can help you identify and articulate the requirements of your project. They can provide you with a quote that is precisely tailored to your needs. Be convinced by their experience and expertise and do not hesitate to contact them to learn more details.

Why is Visoric GmbH from Munich particularly well-suited to professionally support you in the conception and implementation of your AI-powered 3D simulation project

Visoric GmbH from Munich is a leading company in the development of AI-powered 3D simulations. With an experienced and qualified team of developers, scientists, and AI experts, Visoric offers comprehensive support in the conception and implementation of your AI-powered 3D simulation project.

Visoric specializes in developing state-of-the-art and advanced solutions tailored to the specific requirements and goals of the client. They have extensive experience in applying AI technologies across various industries such as architecture, automotive, medicine, and production.

The Visoric team works closely with clients to ensure that the developed solution meets their needs and delivers the expected benefits. They rely on the use of the latest technologies and tools to ensure that the developed solution is stable, scalable, and future-proof.

If you are looking for an experienced and reliable partner to professionally support you in the conception and implementation of your AI-powered 3D simulation project, then Visoric GmbH from Munich is the right choice. Contact them now to learn more details and receive a quote.

What makes Visoric’s 3D simulations special?

Our 3D simulations combine the benefits of high-quality, photorealistic, real-time virtual 3D worlds with the power of artificial intelligence.

This allows our customers to test and customize their products in a realistic environment before they go into production.

This enables faster product readiness and saves time and costs.

How can I commission a 3D simulation from Visoric?

To commission a 3D simulation from Visoric, simply contact us via email or phone.

We will then schedule a consultation to discuss your requirements and preferences.

Based on this information, we will prepare a proposal for project commissioning, proof of concept, or a workshop and collaborate with you on the implementation of your simulation.

Which industries are suitable for 3D simulations?

3D simulations are suitable for many different industries, including automotive, aerospace, medical technology, retail, architecture, and many more.

If you are unsure whether 3D simulations are suitable for your industry, please contact us.

We will advise you competently and individually.

What is the XR Stager, and how can it assist me in 3D simulation?

The XR Stager is a cloud solution platform developed by Visoric GmbH, based in Munich, Germany.

The XR Stager enables the execution of productions based on 3D digital twins, augmented reality, and virtual reality, allowing for the simulation of results.

It also efficiently brings together the work performance of spatially separated teams.

Collaboration and production in the virtual studios of the XR Stager are easily facilitated through the web browser, without the need for software installation or high-performance computers. The XR Stager cloud solution platform conveniently and securely provides the required software, computational power, and workspace for 3D simulation and visualization.

What significance does AI-supported 3D simulation have in the Industrial Metaverse?

AI-supported 3D simulation has many applications in the Industrial Metaverse, ranging from product development to production and maintenance. Some examples include:

Product Development: AI-supported 3D simulations can be used to test products in virtual environments before they are produced in the real world.

Production: AI-supported 3D simulations can be used to optimize production processes and improve the performance of production facilities.

Maintenance: AI-supported 3D simulations can be used to plan and carry out maintenance of equipment and machinery.

Training: AI-supported 3D simulations can be used to conduct training for employees without the need for them to visit the actual facility.

Virtual Reality: AI-supported 3D simulations can be used to enable the use of virtual reality (VR) for product development, production, and maintenance.

AI-supported 3D simulations offer a variety of benefits for industrial production and equipment maintenance.

If you would like to learn more about how this technology can support your business, I recommend contacting Visoric, a company specializing in industrial production solutions and the application of AI-supported 3D simulations.

What does the term AI mean, and what are the different technologies that need to be distinguished within it?

AI, or Artificial Intelligence, refers to the creation of computer systems that possess human-like abilities such as learning, problem-solving, and decision-making.

There are several technologies that fall under the term AI and can be distinguished. Some of them include:

Machine Learning (ML): It involves teaching computer systems to learn from data and recognize patterns without being explicitly programmed.

Natural Language Processing (NLP): It involves enabling computer systems to understand and process human language.

Computer Vision: It involves giving computer systems the ability to understand and interpret images and videos.

Robotics: It involves giving computer systems the ability to control robots and perform tasks.

Deep Learning: Deep learning refers to neural networks with multiple layers and enables solving complex tasks.

Neural Networks: Neural networks are a type of artificial intelligence that attempts to mimic the functioning of the human brain.

There are many other technologies that fall under the AI umbrella. It's important to note that most AI and machine learning technologies complement and influence each other.

How can AI-powered 3D simulations be used in the development of autonomous vehicles?

Which 3D real-time development environments can be coupled and extended with AI technology for 3D simulation?

There is a variety of 3D real-time development environments that can be coupled and extended with AI technology for 3D simulation. Some examples include:

- Unity: Unity is a commonly used development environment for creating 3D real-time applications that can run on a variety of platforms. Unity also supports AI technologies such as machine learning and neural networks, allowing developers to integrate these technologies into their applications.

- Unreal Engine: Unreal Engine is another commonly used development environment for creating 3D real-time applications. It also supports AI technologies like machine learning and neural networks, enabling developers to integrate these technologies into their applications.

- CryEngine: CryEngine is another frequently used development environment for 3D real-time applications. It also supports AI technologies and allows developers to integrate these technologies into their applications.

One successful project that utilizes the combination of 3D real-time development environments with AI technology is the use of Unity and machine learning in the development of realistic digital avatars called 'Digital Human Twins' of human actors for film production and game development.

There are many other successful projects that leverage the combination of 3D real-time development environments with AI technology, such as using CryEngine and AI in the development of realistic 3D simulations for training soldiers and pilots, using Unity and AI in the development of intelligent virtual agents for the customer service industry, and more.

How can I develop a user story and a backlog for my AI-powered 3D simulation project?

A User Story describes a specific functionality that the system should fulfill from the user's perspective. A Requirements Specification (Lastenheft) describes the system's requirements from a technical perspective.

To develop a User Story and a Requirements Specification for an AI-powered 3D simulation project, you can use the following steps and methods:

- Identify the project's target audience and define user requirements.

- Use workshops, interviews, or surveys to gather and prioritize user requirements.

- Formulate user requirements as User Stories by describing user actions, expected output, and benefits.

- Identify the technical requirements necessary to fulfill the User Stories and document them in the Requirements Specification.

- Ensure that the requirements are testable to ensure successful testing during implementation.

- Review and validate the requirements with various stakeholders to ensure they are consistent and complete.

It's essential to ensure that the requirements are clearly and precisely formulated, testable, and aligned with the project's goals.

If you need assistance in developing User Stories and Requirements Specifications for your AI-powered 3D simulation project, I recommend contacting the Visoric team in Munich. They have experience in developing AI-powered 3D simulations and can help you identify and formulate your project's requirements.

What is the significance of Machine Learning (ML) in the development of autonomous vehicles?”

Machine Learning (ML) is a subfield of Artificial Intelligence that allows computer systems to learn from data and make decisions without being explicitly programmed. There are various types of ML, including supervised learning, unsupervised learning, and reinforcement learning.

An example from the automotive industry where ML plays a role, is the development of autonomous vehicles. In this case, ML can be used to enable the vehicle to learn from the data it receives through its sensors and make decisions. For example, an autonomous vehicle can use cameras and laser scanners to perceive its surroundings and then use ML algorithms to decide how to behave in traffic.

In the automotive industry, Virtual Reality and Serious Gaming are also used to facilitate the development and testing of autonomous vehicles in a realistic environment. For instance, a virtual driving simulator can be used to test the autonomous vehicle in a virtual environment and adapt its decisions and actions to different scenarios. ML can be used to improve the decisions of the autonomous vehicle based on the experiences it gathers in the simulator.