Mixed Reality Assembly Platform in Industrial Use

Image: © FIR e. V. at RWTH Aachen | Implementation: Ulrich Buckenlei – Visoric GmbH

Assemble More Efficiently with XR and AI

How can complex assembly processes be made more understandable, faster, and error-free? A new project at FIR e. V. at RWTH Aachen demonstrates how modern technologies can make this a reality. Using Mixed Reality and Artificial Intelligence, a digital assembly platform was developed that can serve as a practical model for the automotive industry.

- Research Partner: FIR e. V. at RWTH Aachen

- Technology Used: Mixed Reality, AI, 3D visualization

- Demonstrator: LEGO Technic model as a real-world scenario

Assembly Platform in Mixed Reality

Image: © Ulrich Buckenlei – Visoric GmbH | Implementation for FIR e. V. at RWTH Aachen

The idea behind the project: to provide digital instructions that appear directly in the user’s field of view – exactly where the work takes place. This creates real added value for training, assembly, and maintenance in industry.

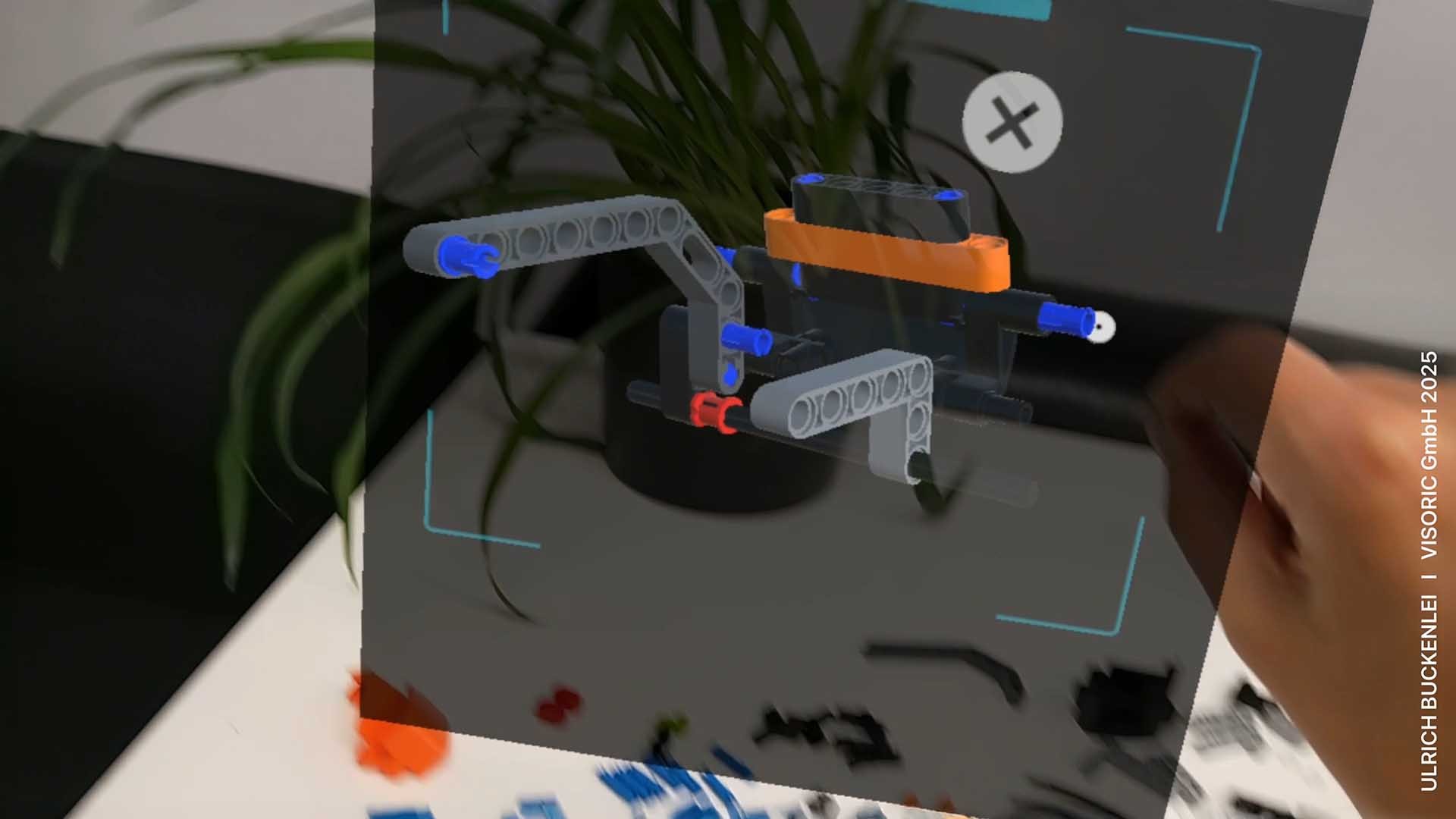

Assembly with HoloLens: Step-by-Step at a Glance

The Microsoft HoloLens 2 becomes an interactive assistant: 3D instructions are projected onto real objects, precisely positioned, and adjusted in real time. Users can move freely, zoom, or rotate – all while staying on the correct assembly step.

- Spatially Precise Overlays: Assembly information directly in the field of view

- Intuitive Operation: User guidance without external displays or manuals

- Faster Workflows: Reduced training and assembly times

3D Assembly Instructions with HoloLens

Image: © Ulrich Buckenlei – Visoric GmbH | Implementation for FIR e. V. at RWTH Aachen

Especially in industries with complex production chains, this technology can make a real difference. It reduces sources of error and helps new employees get up to speed faster. A clear advantage – especially in times of skilled labor shortages.

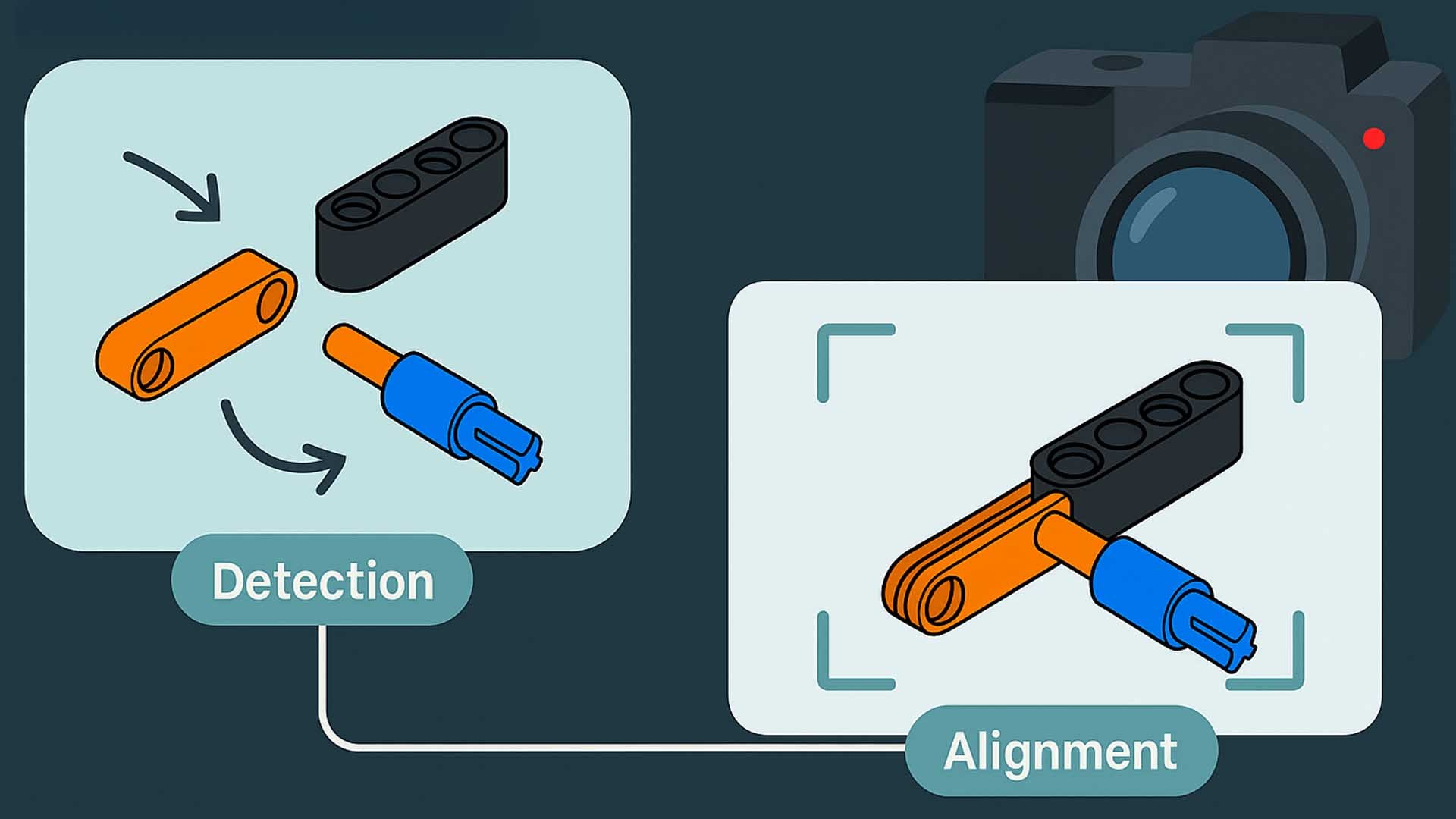

AI Recognizes Components and Automatically Displays Instructions

A key feature of the platform is the integration of AI-based object recognition. The technology automatically detects which component the user is holding – and instantly displays the corresponding assembly step. This saves time and significantly improves efficiency.

- Real-Time Object Recognition: Analysis of shape, color, and position

- Dynamic Adjustment: Instructions change automatically with each step

- Process Optimization: Less time spent searching, more focus on the task

Infographic: Object Recognition and Step Alignment

Graphic: © Ulrich Buckenlei – Visoric GmbH

This function clearly shows how Artificial Intelligence can act as an assistance system – without being overwhelming. It supports, guides, and relieves at the same time. The human stays at the center – the technology becomes a helpful extension.

Video Insight: The System in Real Operation

A short video demonstrates the complete workflow: from component recognition to step-by-step instructions to the finished assembly. Particularly impressive: a previously two-hour assembly process is completed in just 30 minutes – with the same quality.

- Realistic Application: Assembly in a production environment

- Narrated Explanation: Voiceover provides insight into UX and technology

- Learning Resource: Video usable for training and presentation

Video: Assembly Platform in Action

Video: © Ulrich Buckenlei – Visoric GmbH | Implementation for FIR e. V. at RWTH Aachen

New Ways of Guidance – Your Options

Assembly processes, training, or product onboarding can now be reimagined: immersive, intuitive, and efficient. The combination of XR and AI opens up possibilities that go far beyond traditional work instructions. Those who digitalize now will gain lasting advantages.

- Planning & UX: From idea to interactive user guidance

- XR Applications: Development of HoloLens-compatible apps

- AI Integration: Intelligent assistance systems for process support

Interested companies will find in the XR and AI approach a future-ready tool for training and production. Those who want to learn more or reevaluate their processes will find the right entry point for discussion here.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich