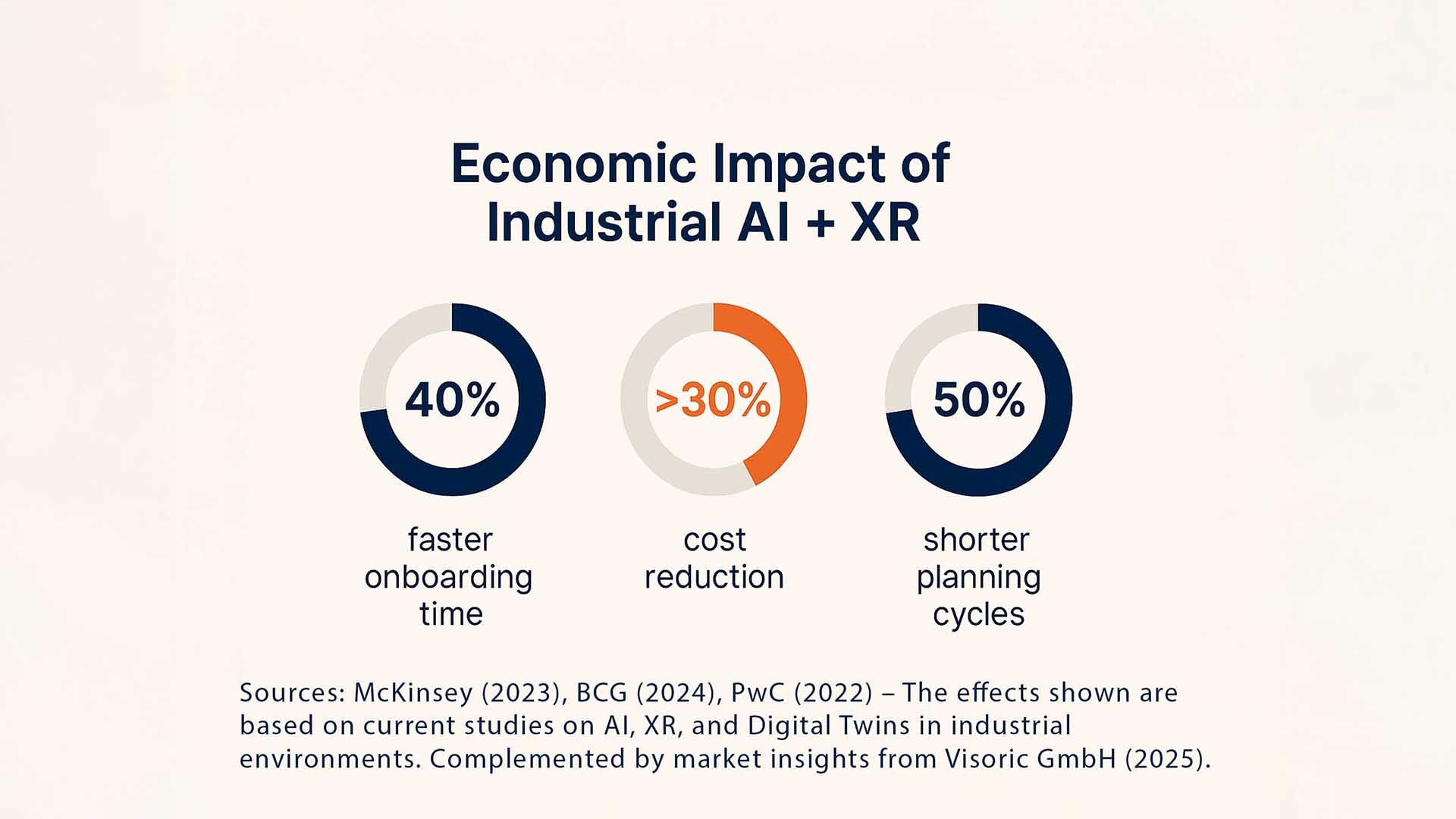

Image credit title graphic: Visoric based on data from McKinsey, BCG, PwC | Design by Ulrich Buckenlei

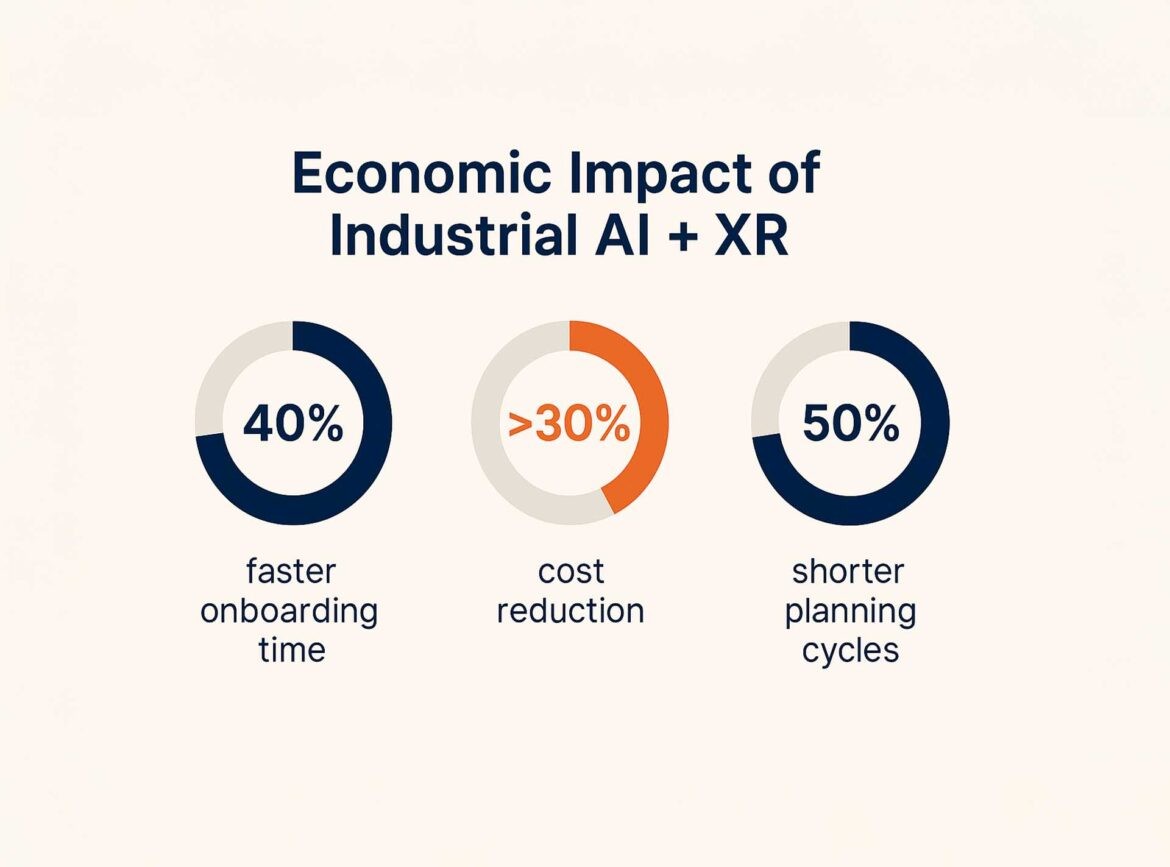

The fusion of Artificial Intelligence (AI) and Extended Reality (XR) is no longer just a technological trend – it is fundamentally transforming industrial value chains. The new title graphic highlights the tangible effects: 40% faster onboarding, over 30% cost savings, and a 50% reduction in planning cycles – according to studies by McKinsey, BCG, and PwC. In the following article, we showcase how these potentials can be realized – with examples, graphics, and real-world use cases.

Sources: McKinsey (2023), BCG (2024), PwC (2022) – The effects shown are based on current studies on AI, XR, and Digital Twins in industry. Supplemented by market insights from Visoric.

New Perspectives in Production

Industrial manufacturing is undergoing a fundamental transformation. What was once dominated by mechanics and classic automation is now driven by AI, immersive interfaces, and real-time data. Production lines are evolving into adaptive ecosystems – intelligent, visual, and connected.

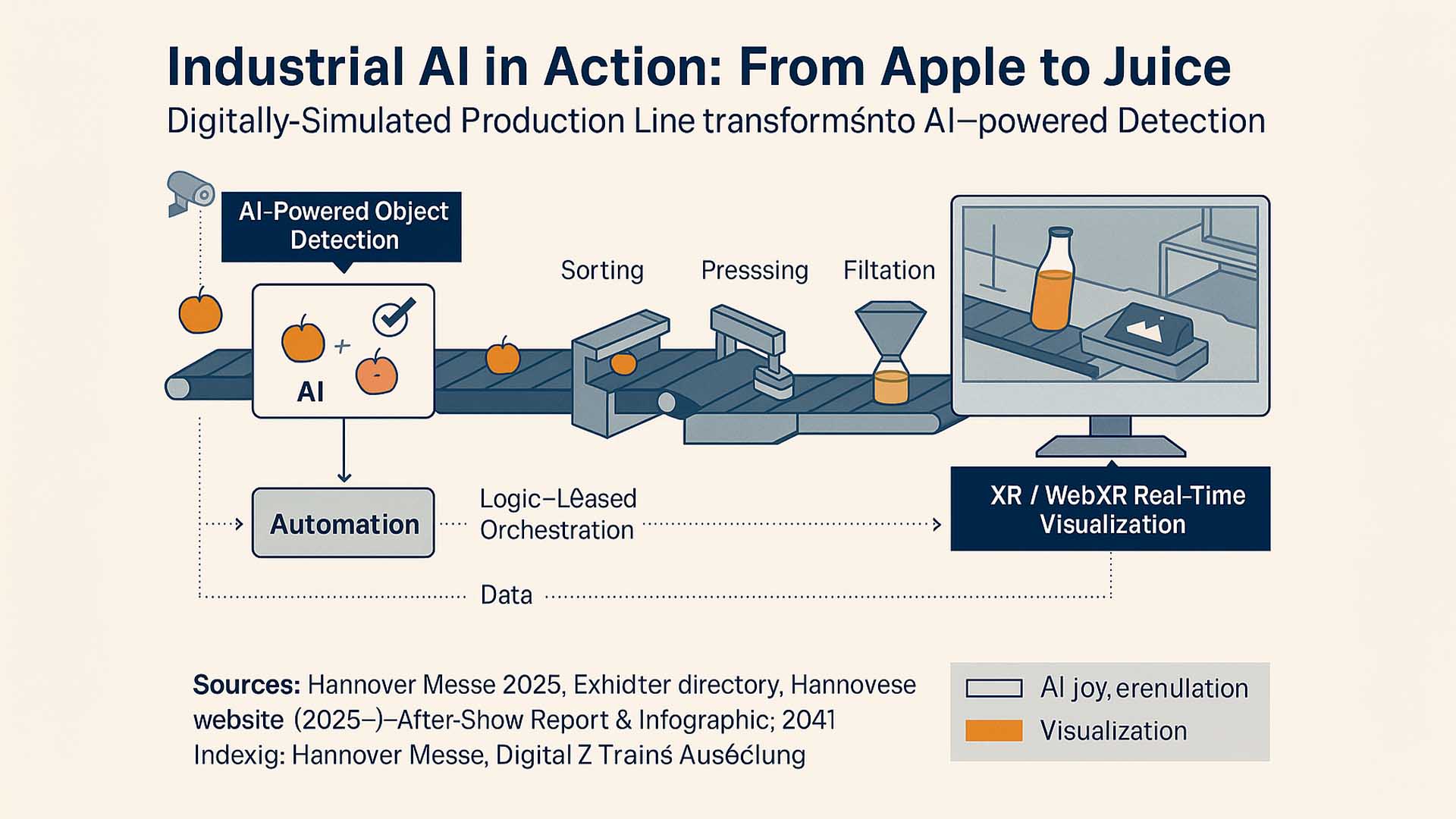

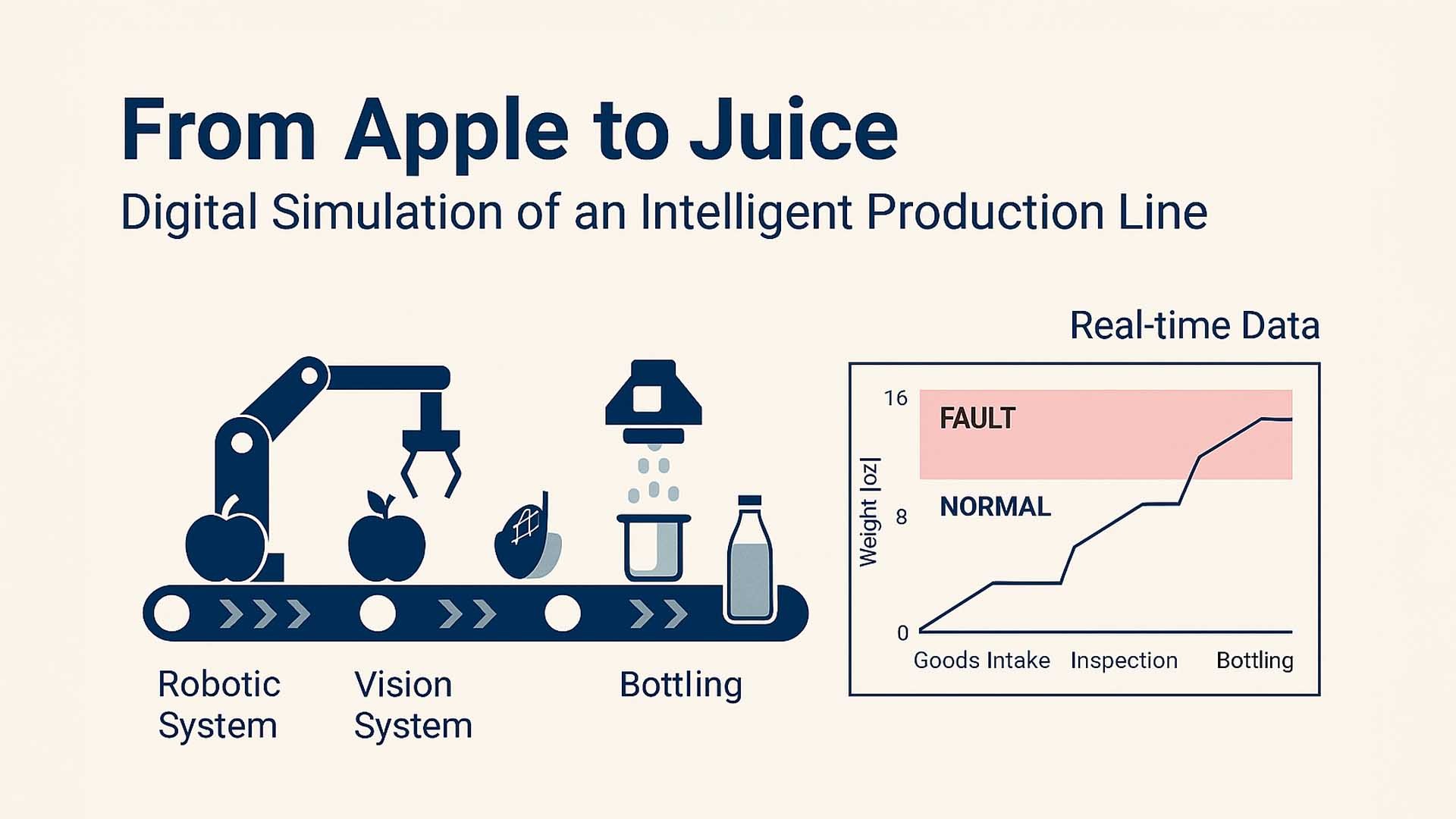

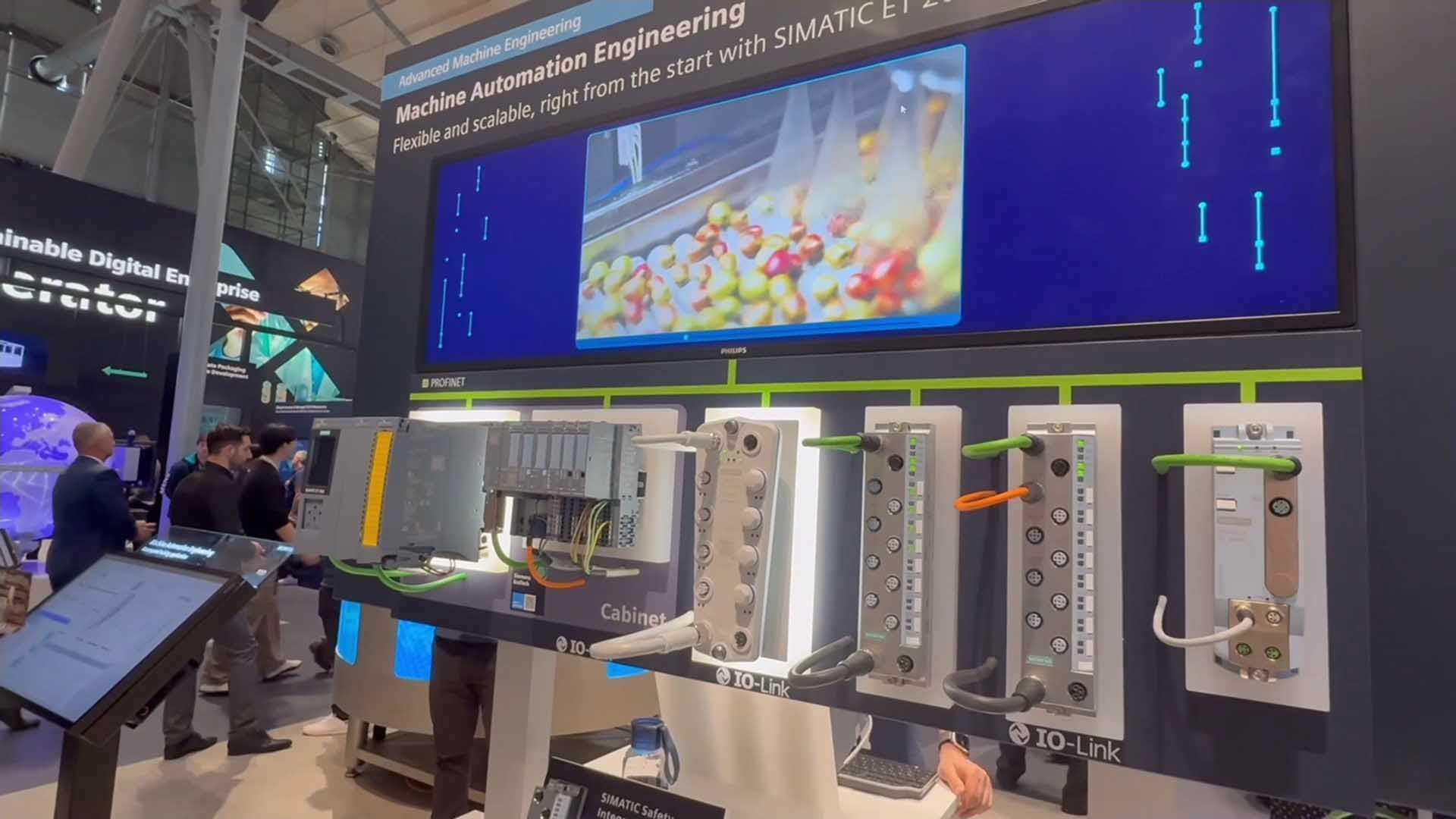

At Hannover Messe 2025, this development became clear: with the real-time installation “From Apple to Juice,” Visoric and Siemens demonstrated how AI-powered systems can control an entire production chain – from delivery to bottling – visualized in an immersive 3D environment.

From Apple to Juice – Process Flow

Image credit: Visoric / Siemens | Visualization of the production chain with AI + XR

This graphic visualizes the entire production process – live controlled by AI, enriched with sensor data, and simulated in an immersive XR environment. Every stage is traceable, every decision transparent.

From Automation to Cognitive Systems

The difference to traditional systems? Intelligence. AI detects patterns, predicts errors, and optimizes processes. XR makes these processes visible and intuitively controllable – in real time, collaboratively, and from anywhere.

The advantages range from shorter response times to improved training outcomes and increased safety through predictive maintenance. Interactive spaces are created in which processes are not just understood but experienced.

The Intersection of AI + XR

Image credit: Visoric | Visualization of the conceptual connection between AI & XR

This graphic illustrates how algorithmic intelligence and immersive technologies reinforce each other. Data becomes experience, systems become comprehensible tools.

Architecture of the Intelligent Factory

At the core is a clearly structured tech architecture: sensors, automation, AI, digital twins, and XR form a smart stack model. Each layer plays a defined role – from data collection to remote control.

Companies that implement this model today secure not only efficiency – but also resilience, innovation, and future-readiness.

The AI-Enhanced Factory Stack

Image credit: Visoric | Five levels for smart production

From sensors to XR – the stack model shows how modern factories operate as connected systems. Each level communicates with the next – fully orchestrated by AI.

Tangible Value: Economic Effects

What does this mean for the bottom line? According to McKinsey, immersive training can save up to 40% of onboarding time. BCG cites over 30% lower costs through AI-driven maintenance. And PwC reports that planning cycles can be cut in half with immersive digital twins.

These figures are now visualized in the new title graphic “Economic Impact of Industrial AI + XR” – both as an introduction and proof of performance.

Economic Impact of Industrial AI + XR

Image credit: Visoric based on data from McKinsey, BCG, PwC

The visualization shows: AI + XR are not cost drivers – they are performance accelerators with a measurable ROI. Efficiency, quality, and speed improve significantly.

Immersive Installation at Hannover Messe

Image credit: Ulrich Buckenlei | Photographed in the Siemens Experience Area

A glimpse into the immersive environment at Hannover Messe: visitors experience the interaction of AI and XR – intuitive, adaptive, and industrial-grade.

The experience is based on real production data – including control, feedback, and simulation.

Digital Twin in Action

Image credit: Ulrich Buckenlei | Real-time capture from the XR visualization

The visualization shows the real-time connection of sensors, AI, and XR. Motion data, temperature curves, and machine dynamics – all visible in one space.

This turns control into experience – and complexity into advantage.

Video: From Apple to Juice – The Digital Production Flow

Video source: Visoric / Siemens | Real-time process – visualized with AI + XR

Video: © Ulrich Buckenlei | XR Stager NewsRoom Team

The video showcases the entire digital value creation process – including real-time control, AI decision logic, and immersive representation. A preview of tomorrow’s industry.

Personalized Consulting for Your AI/XR Projects

Would you like to realize your own AI/XR projects or implement immersive tools into your value creation process?

The Visoric expert team will guide you – from strategy to implementation. With experience, vision, and technological expertise.

Learn more at www.visoric.com or connect directly via LinkedIn: Ulrich Buckenlei

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich