Immersive 3D assembly instructions with Apple Vision Pro in action.

Photo © Visoric: Ulrich Buckenlei interacts with the Siemens Nema Class 14 model on the Apple Vision Pro Spatial Computing Headset in the BILT app, 2024.

Digital Twins: The Future of Manufacturing

The introduction of digital twins is revolutionizing efficiency, precision, and scalability in modern manufacturing. By simulating and analyzing real objects in a virtual environment, companies can optimize and improve processes before a physical prototype is needed.

- Production optimization: Save time and resources with precise simulations.

- Increased product quality: Identify and fix errors early on.

- Scalability: Quickly adapt to market needs and customer desires.

This technology represents a turning point in the industry and offers immense benefits for companies worldwide.

Innovative simulations for the industry – Digital Twins.

Image © Visoric: The advanced use of digital twins enables a new dimension of product development, 2024.

In the next chapter, we will explore the crucial role of VR, AR, and spatial computing glasses in advancing digital twins and immersive 3D instructions.

Here’s the translation for your request:

VR, AR, and Spatial Computing Glasses: Keys to Interactive Instruction

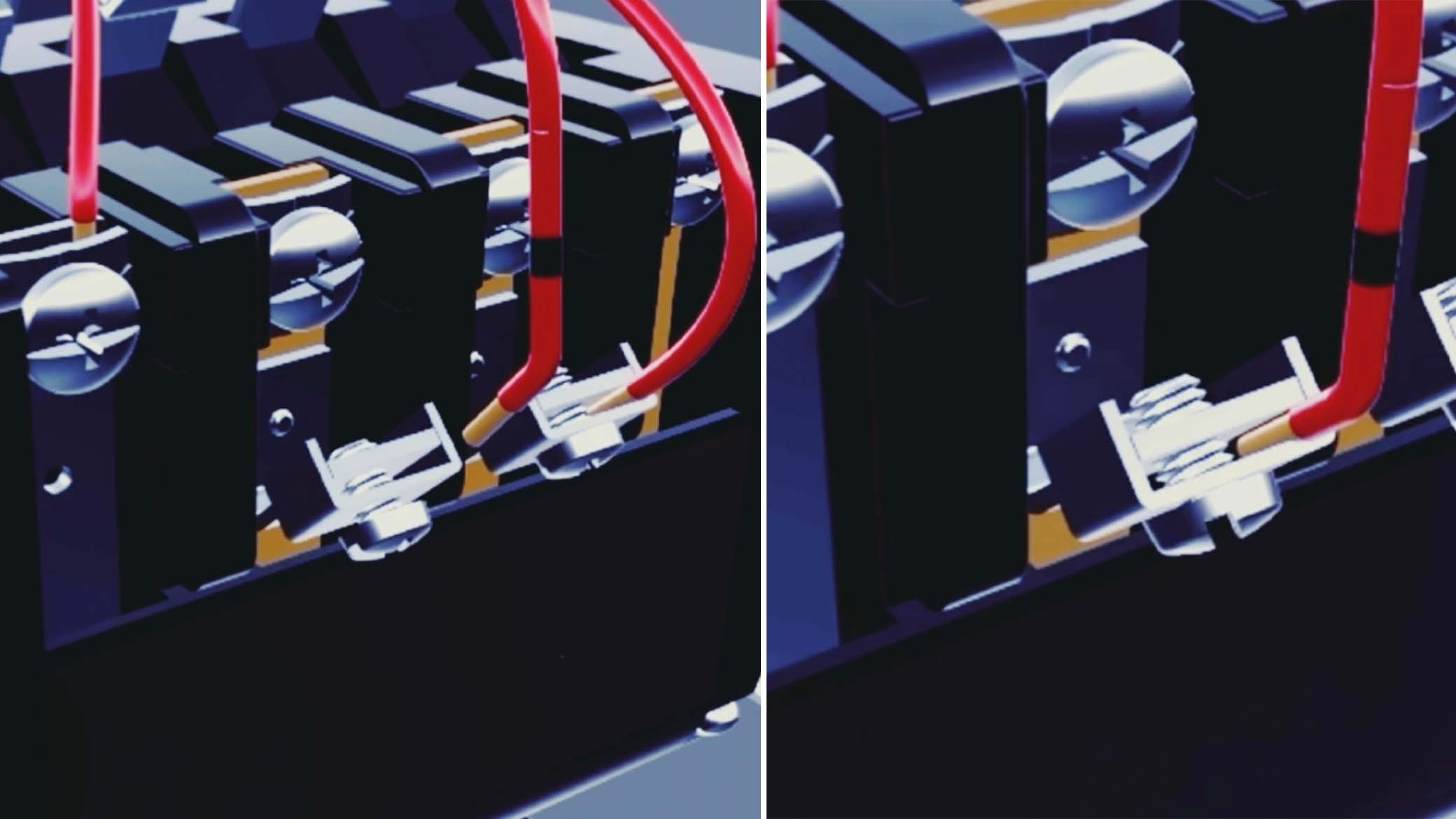

The integration of VR, AR, and spatial computing glasses opens up new possibilities in interactive assembly instructions. These technologies enable users to better understand and perform complex assembly steps through immersive visualizations.

- Interactivity: Users can follow assembly steps in an interactive 3D environment.

- Precision: Detailed representations ensure correct assembly execution.

- Understandability: Complex processes are made easier to understand through visual aids.

These glasses are not only tools for professionals but also for laypeople who want to assemble complex products themselves.

Two frames of a wiring animation: Error and correction.

Image © Visoric: Insights into the step-by-step wiring instruction – from incorrect to correct execution, 2024.

In the next chapter, we delve deeper into the world of immersive 3D assembly instructions and explore how they improve efficiency and precision in assembly processes.

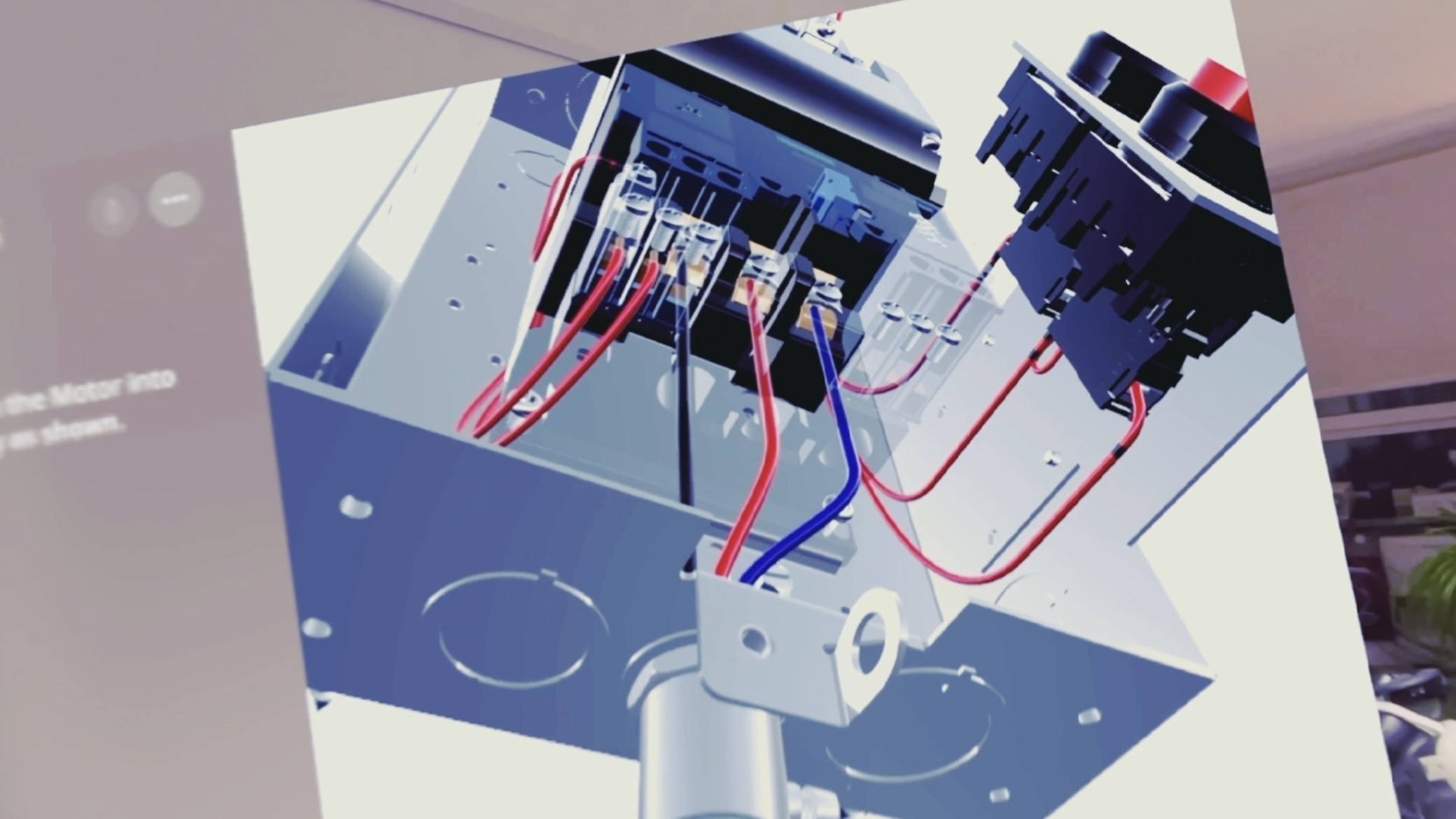

Immersive 3D Instructions: A Look Through the Apple Vision Pro

The Apple Vision Pro and the XR Stager Industrial Metaverse and Spatial Computing platform are revolutionizing how we interact with digital content. Led by digitalization strategist Ulrich Buckenlei, this combination provides an immersive experience that blurs the lines between the physical and digital worlds.

- Seamless Integration: Perfect harmony between hardware and software.

- Extended Reality: A deeper dive into digital content.

- Industrial Application: Practical use cases across various industries.

This technology promises to enhance the efficiency of learning and work processes while opening up new possibilities for the industry.

Ulrich Buckenlei demonstrates the XR Stager platform on the Apple Vision Pro.

Image © Visoric: Ulrich Buckenlei presents how the XR Stager platform runs on the Apple Vision Pro, 2024.

In the next chapter, we will examine how companies are using these technologies to optimize their processes and transform the way we learn and work.

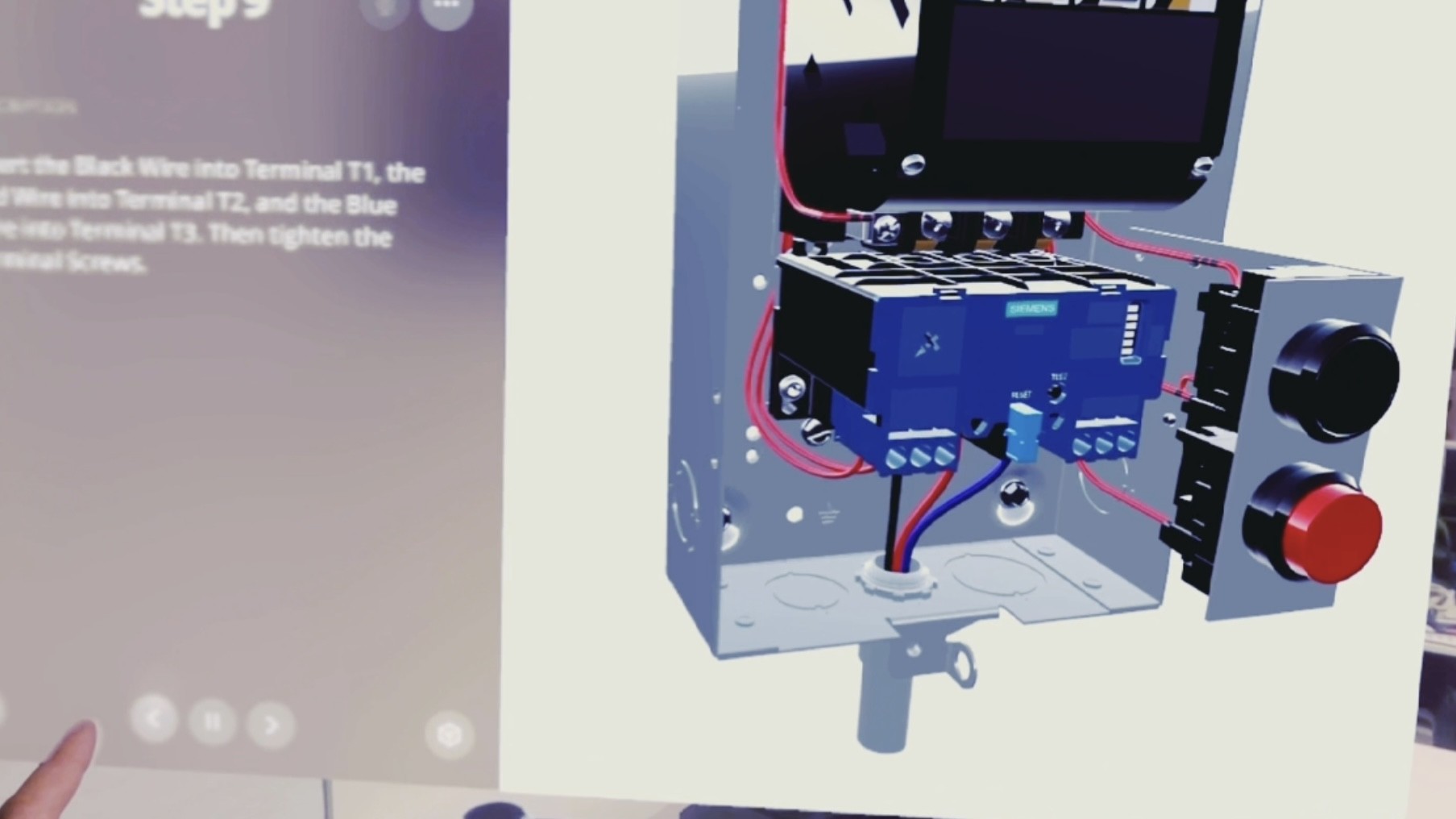

Case Studies and Examples: Siemens Electrical Installation Products

The implementation of immersive 3D assembly instructions is particularly impressive with Siemens electrical installation products. By utilizing interactive digital twins based on the manufacturer’s CAD data, the assembly process is not only simplified but also made significantly more vivid.

- Interactive Instruction: Step-by-step assembly in 3D.

- Digital Twins: Precise models based on CAD data.

- Industry Application: Efficiency gains in electrical installation.

This innovative approach opens up new perspectives in product assembly and maintenance.

Interactive digital twin facilitates the assembly of Siemens electrical installation products.

Image © Visoric: An example of the step-by-step assembly instruction in use, 2024.

The following chapter will shed light on the future developments expected in the technology of immersive 3D instructions and digital twins.

Here’s the translation for your request:

The Future of 3D Assembly: Insights Through the BILT App Review

Discover the future of 3D assembly instructions through our exclusive review video of the BILT app on the Apple Vision Pro. The video impressively demonstrates how the Siemens Nema Class 14 model is brought to life with the help of this innovative technology.

- Interactive Demonstration: Detailed step-by-step guide.

- Technological Innovation: Use of the Apple Vision Pro.

- Practical Example: Assembly of the Siemens Nema Class 14 model.

This visual tour offers a fascinating insight into the capabilities of modern assembly instructions.

Exploring the future of 3D assembly with the BILT app on Apple Vision Pro.

Video © Visoric: A review of the BILT app as it visualizes the Siemens Nema Class 14 model on the Apple Vision Pro, 2024.

Ready for the Future?

The technologies presented open a new chapter in the way we work and learn. Immersive 3D assembly instructions and digital twins are just the beginning. We are on the threshold of an era where interactivity and efficiency are redefined.

- Shaping change: Be part of the innovation.

- Expanding knowledge: Deepen your understanding of forward-looking technologies.

- Utilizing expertise: Benefit from our expertise and experience.

Would you like to delve deeper into the world of immersive technologies or directly experience how these innovations can transform your company? Visit our contact form on the website, send us an email, or call us. Our expert team at Visoric looks forward to guiding you into an interactive and efficient future.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: + 49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 München