Telepresence with Mixed Reality: Merging Human and Machine through XR Control and AI-Driven Robotics.

Image: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

With the rapid development of immersive technologies, a new form of industrial interaction is emerging: Telepresence 2.0. Remote control is no longer limited to screens and joysticks. Instead, mixed reality headsets such as the Meta Quest 3, Varjo XR-4, or Apple Vision Pro enable an intuitive fusion of human and machine. Operators can control robots remotely with the highest precision – and in real time. The result: greater safety, improved efficiency, and entirely new forms of human-machine integration.

The Key Technologies: Digital Twins, Haptics, and Immersion

At the core of this development are digital twins – real-time 3D models of robots and their environments. These are visualized in XR environments and allow mechanical responses to be anticipated in advance. Through haptic feedback – via gloves or suits – users can feel resistance, weight, or motion. This not only makes the control process more efficient but also significantly safer.

- Immersive 3D models in real time

- Tactile feedback during interaction

- Predictive collision avoidance

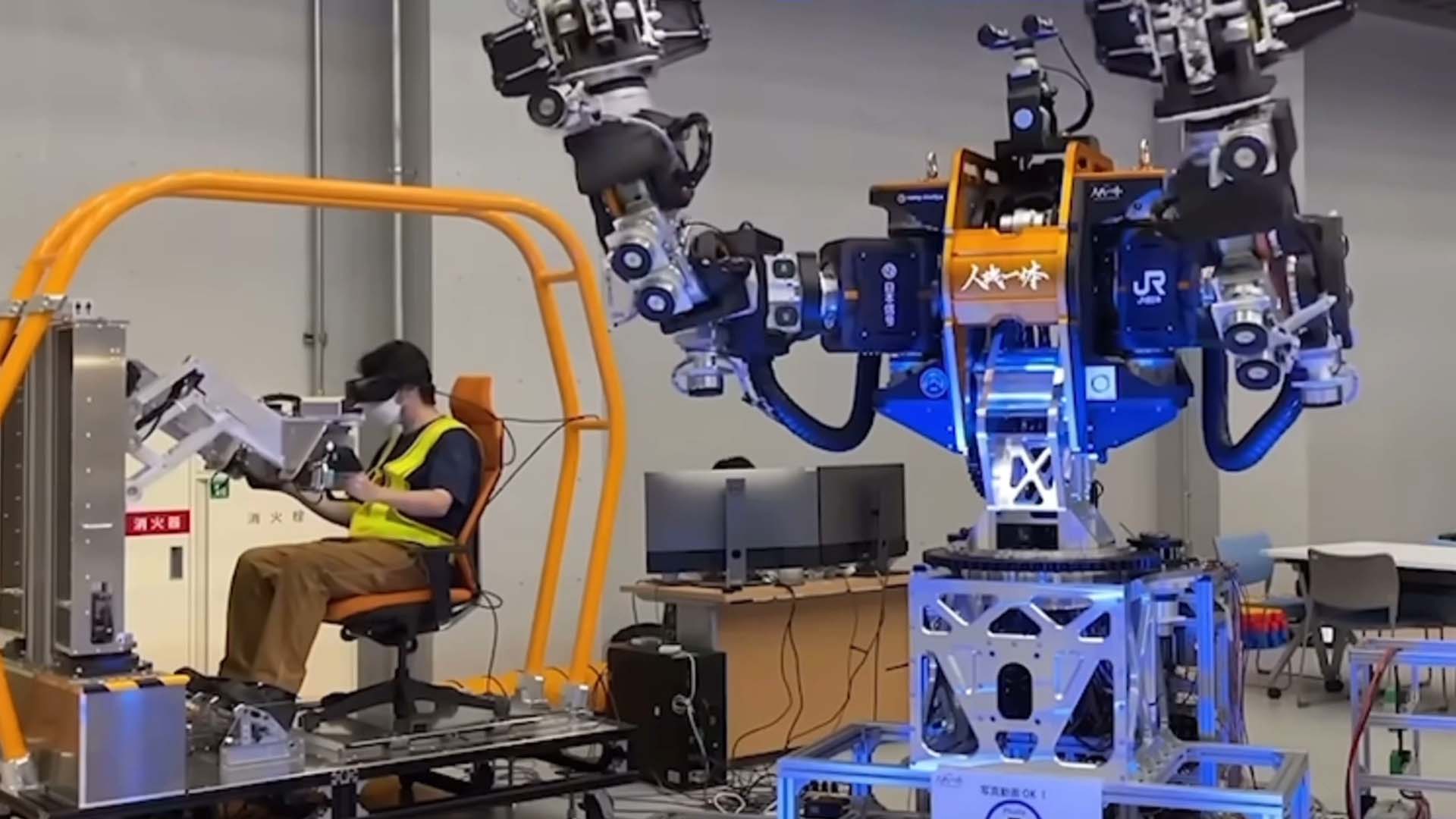

XR Control in Action: An operator precisely controls every movement of a robot – via headset and haptic interface.

Image: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

The fusion of visual depth, physical feedback, and digital simulation sets a new standard for modern machine operation.

Industrial Avatars: Robots as an Extension of the Body

These machines are no longer just tools – they are industrial avatars. The human mind remains the conductor, but execution is carried out by a physical entity. Using depth perception, eye tracking, and real-time data, users can intuitively operate the robot’s body. Decisions are made contextually and with high precision.

- Full-body telepresence via XR

- Controlled gestures and gripping motions

- Deployment in safety-critical environments

Operator Station: With VR headset and control arms, robots become tangible tools in the user’s hands.

Image: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

Machines thus become an extension of human capabilities – regardless of location or physical ability.

Real-World Applications: XR Robotics in Action

Whether for tunnel inspections, energy grid maintenance, or precision assembly – XR-controlled robotics is already a reality. Companies use it to access hazardous or hard-to-reach areas – while reducing error rates at the same time.

- Energy: Inspection of offshore wind turbines

- Transportation: Railway infrastructure repair

- Manufacturing: Precision work under time pressure

Modern robotic arms perform tasks in harsh environments – precisely controlled through XR technology.

Image: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

This technology not only transforms daily work – it protects lives and opens up new business models.

Access & Diversity: New Roles for New Generations

What once required physical strength now relies on cognitive skill. With the right XR systems, an intern can perform complex tasks just like a seasoned engineer. Senior experts or individuals with disabilities also gain new opportunities in industrial environments.

- Barrier-free access to Industry 4.0

- Competence-based rather than physical work

- Extended careers for experienced professionals

Deployment in hard-to-reach locations: Robots take over dangerous tasks – controlled via secure XR systems.

Image: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

XR robotics democratizes the workplace and fosters a more inclusive industrial environment.

Outlook: The Immersive Now – with VISORIC

Robots of the future are intelligent, immersive, and human-guided. With XR, distance disappears – only vision, data, and precision remain. VISORIC combines XR expertise with industrial solutions and implements safe, scalable XR robotic processes for companies of all sizes.

- XR consulting and feasibility studies

- Custom prototypes and control solutions

- Integration into existing operations

15 years of experience in 3D, AI, XR, and robotics – your VISORIC expert team from Munich.

Visualization: Ulrich Buckenlei / Visoric GmbH

Immersive robotics is not a future scenario – it is operational now. If you want to integrate XR into your processes, VISORIC is your ideal partner.

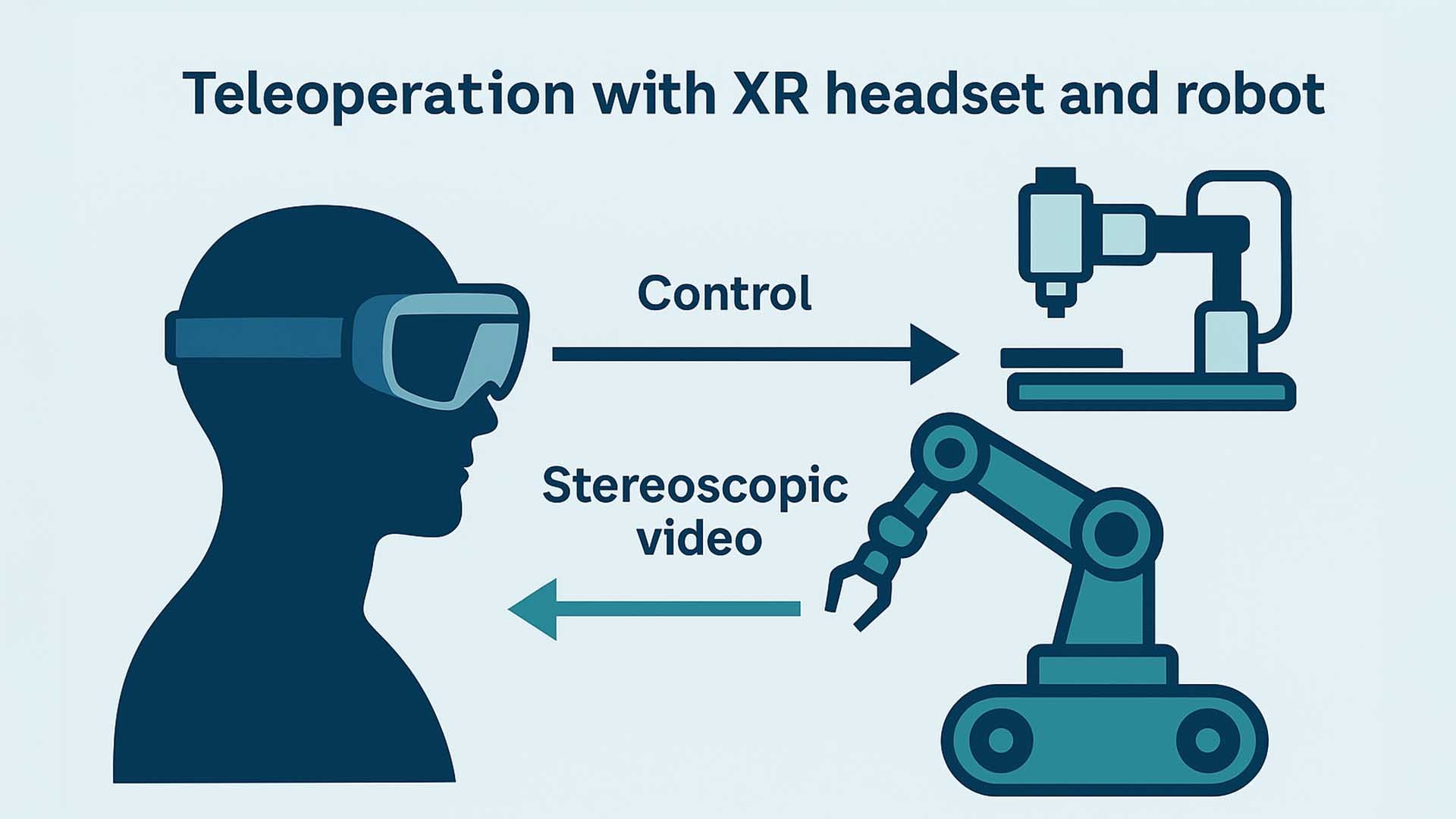

Remote Control via XR – Connecting Humans and Machines

Schematic Illustration: Control via XR headset and feedback through stereoscopic video transmission.

Visualization: Ulrich Buckenlei / Visoric GmbH

The XR headset enables precise remote control of a robot, while the robot transmits its stereoscopic camera image back to the operator – for maximum control and situational awareness.

Video: XR Meets Robotics – How Telepresence 2.0 Works

Modern robotic arms perform tasks in harsh environments – precisely controlled through XR technology.

Video: Unstoppable Gadgets YouTube Channel, Editing: Ulrich Buckenlei

Get in Touch: Start XR Robotics with the VISORIC Expert Team

Do you want to implement XR-supported robotics in your company? Then talk to the experts at VISORIC:

- We provide individual, vendor-neutral consulting

- We develop tailored prototypes for your industry

- We guide you from concept to implementation

Take advantage of Telepresence 2.0 – together with the leading XR partner from Munich.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich