Industrial AI as a practical factor: At FUTUREPRINT TECH in Munich, it became clear how artificial intelligence accelerates development processes in the automotive industry and how simulation evolves from a testing tool into an active innovation engine.

Photo: Ulrich Buckenlei | FUTUREPRINT TECH 2026

Why Industrial AI is more than consumer AI

When artificial intelligence is discussed in an automotive context, many people first think of autonomous driving or digital assistance inside the vehicle. The presentation by industry analyst Ulrich Buckenlei deliberately started earlier in the value chain. The focus was on how AI is already changing the way vehicles are developed, tested, validated, and ultimately built.

The decisive difference lies in the data foundation and in responsibility. Industrial AI does not learn from internet data, but from reliable industrial measurements, sensor data, machine states, and production lines. This AI does not learn what the world looks like, but how it behaves. Errors have real consequences. This is why models must be explainable, deterministic, and robust, and integrated into systems that have evolved over decades.

- Industrial data → Learning from machines, sensors, and real processes instead of web content.

- No tolerance for errors → Decisions must be traceable and reliable.

- Value emerges in the system → Impact only arises through integration into real workflows.

Industrial AI in reality: The presentation made it clear that AI in industry only becomes relevant when it is connected to real data, clear responsibility, and concrete process goals.

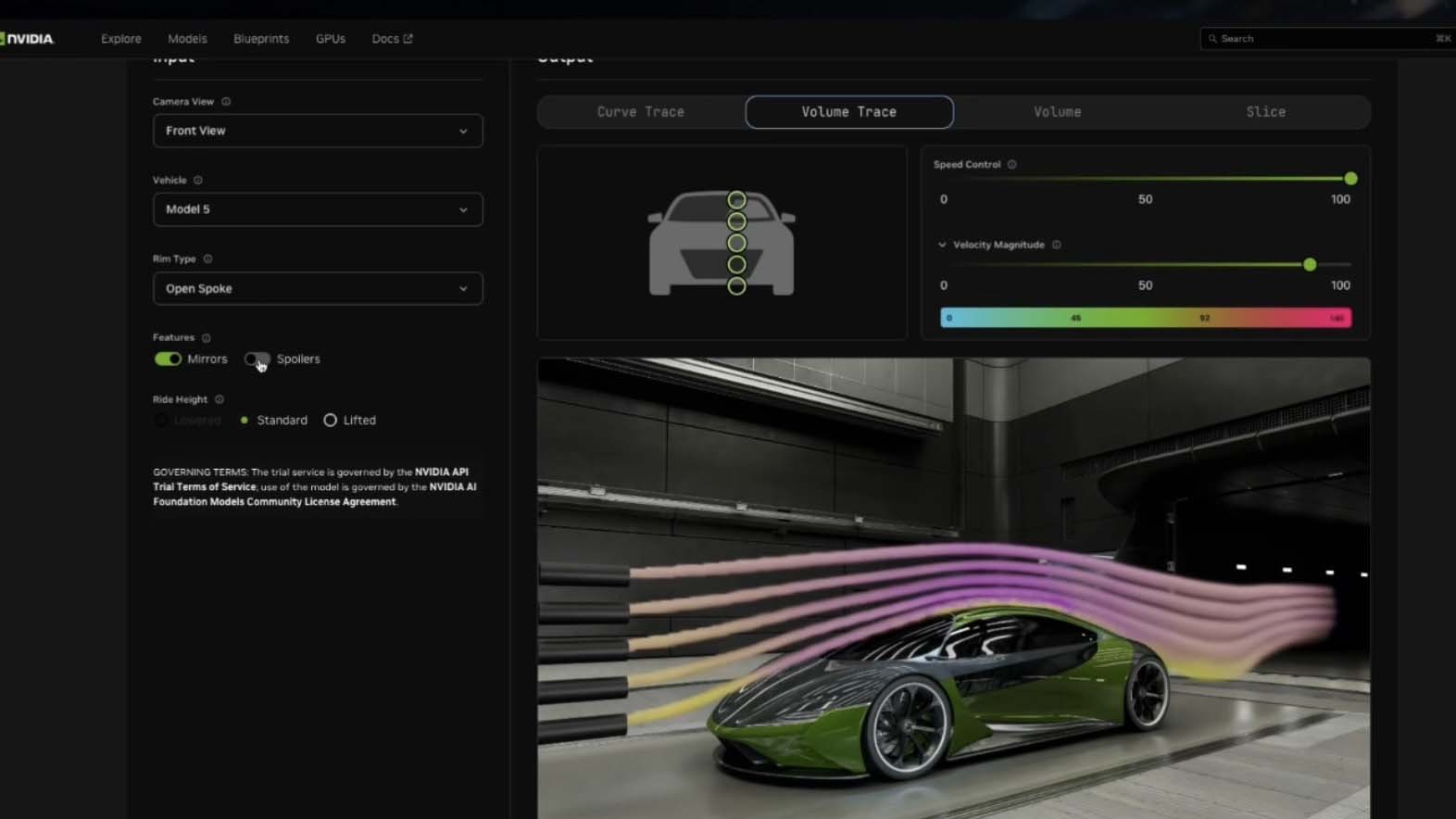

Visualization: Ulrich Buckenlei | Presentation Accelerating Automotive Innovation with AI FUTUREPRINT TECH 2026

For companies, this leads to a new guiding question. Not whether AI is used, but how it shortens development cycles, makes risks visible earlier, and measurably improves engineering decisions.

Simulation becomes an accelerator in vehicle development

A key focus of the presentation was simulation as the bottleneck of modern development. In aerodynamics, accuracy is not the main challenge, iteration speed is. Physical wind tunnels are expensive and limited. High-fidelity simulations are computationally intensive and often take hours or days. Slow iteration means less exploration and fewer opportunities to discover better variants early.

AI fundamentally changes this process. Models trained on large numbers of simulations and test datasets do not start from zero. They identify sensitivities, focus computational effort on critical flow regions, and deliver reliable trends much faster. Speed is created not only by hardware, but by experience embedded in the model.

- Faster iteration → AI shortens cycles by learning from previous cases.

- Earlier decisions → Feedback moves into the design phase while options are still open.

- Exploring more variants → Exploration becomes scalable instead of limited to a few runs.

Iteration instead of stagnation: AI-driven simulation shifts the focus from late to early phases and turns validation into a continuous decision-making process.

Photo: Ulrich Buckenlei | CES 2026

Simulation is therefore no longer just a final verification tool. It becomes an active navigation aid in engineering and expands the space of possible solutions.

Virtual testing becomes more targeted and production systems start learning

In traditional approaches, many problems appear late, when prototypes are built and real tests are conducted. Each test costs time and money. AI shifts the focus here as well. Trained models highlight risk areas, prioritize scenarios, and help prepare tests more effectively. Fewer tests are required, but the tests that do take place are far more targeted.

A further step emerges when simulation does not end before production. AI can learn from ongoing production data and continuously update digital models. Deviations, drift, and potential bottlenecks become visible earlier. A static digital twin turns into a learning system that stabilizes planning and operations instead of merely documenting them.

- Smarter testing → Focus on risk instead of the volume of test runs.

- Continuous learning → Production data keeps models current and grounded in reality.

- Fewer surprises → Problems become predictable instead of reactive.

From static to living systems: When digital twins learn from real operational data through AI, systems emerge that detect risks earlier and stabilize operational decisions.

Visualization: Ulrich Buckenlei | Presentation Accelerating Automotive Innovation with AI FUTUREPRINT TECH 2026

Especially in the automotive industry, where every change triggers chain reactions, this approach becomes a lever for making complexity manageable and for rethinking development speed.

From vision to execution, where Industrial AI still struggles today

Despite visible progress, the presentation also made clear why Industrial AI is not a self-running system. Data is often fragmented, difficult to access, and not consistently quality-assured. Trust is another key issue. In industry, a plausible result is not sufficient. Engineering teams must understand why a system makes a recommendation. Explainability is not optional, it is a prerequisite.

The third limiting factor is integration. AI must work together with CAD, PLM, simulation software, and shopfloor systems. Many of these tools were not designed for AI. The fourth factor is cultural. New workflows must gain acceptance. Trust is built through transparency, training, and gradual introduction.

- Data quality → Without clean pipelines, AI cannot learn reliably.

- Explainability → Engineers need transparency instead of black boxes.

- Integration and culture → Impact only emerges when systems and teams align.

Industrial AI needs a foundation: The path to practice leads through data pipelines, integration into existing systems, and the willingness to evolve workflows step by step.

Visualization: Ulrich Buckenlei | Presentation Accelerating Automotive Innovation with AI FUTUREPRINT TECH 2026

Anchoring Industrial AI, simulation, and 3D workflows strategically

The presentation at FUTUREPRINT TECH showed that Industrial AI does not create value through individual tools, but through the connection of data, simulation, model understanding, and well-integrated workflows. This is exactly where the Visoric expert team from Munich operates, focusing on AI, spatial computing, and industrial 3D pipelines.

Visoric supports companies in transforming complex CAD and process data into scalable, spatially usable systems and embedding AI-driven simulation and decision processes into real value chains. The goal is not short-term impact, but a robust foundation that improves development, operations, and communication over the long term.

The VISORIC expert team: Ulrich Buckenlei and Nataliya Daniltseva discussing Industrial AI, simulation-driven workflows, and spatial 3D strategies for industry.

Source: VISORIC GmbH | Munich 2025

The scope of services deliberately goes beyond visualization. Visoric accompanies companies across the entire value chain of real-time 3D and Industrial AI, from analyzing existing data landscapes and prototyping to proof-of-concepts and productive use in development, training, service, and communication.

- Strategic conception of AI-driven simulation and digital twin workflows based on existing CAD data.

- Development of prototypes and proof-of-concepts for rapid evaluation of technological and organizational feasibility.

- Building scalable software solutions for industrial, service-oriented, and communication applications.

- Integration of real-time 3D, mixed reality, and Industrial AI into existing processes and toolchains.

- Cross-platform use of 3D assets across headsets, web, desktop, and mobile devices.

Whether the goal is faster iterations in vehicle development, more focused testing, learning production models, or consistent technical communication, a stable technical and organizational foundation is decisive. Visoric brings this experience and supports companies in not only introducing Industrial AI, but anchoring it effectively over the long term.

If you would like to explore how AI-driven simulation, digital twins, and spatial 3D workflows can be concretely transferred to your organization, a conversation with the Visoric expert team provides a solid foundation for the next steps.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich