Flying AI with Autonomous Drones in Industrial Operations

Visualization: © Ulrich Buckenlei | Conceptual illustration of autonomous drones in industrial environments | No claim of technical accuracy

Autonomous flying drones are quietly but fundamentally transforming everyday industrial operations. They take on tasks that are risky, inefficient, or unsustainable for humans over the long term, such as work on critical infrastructure, at great heights, under extreme weather conditions, or in hard to access environments. What is emerging is not a future vision, but a new operational reality.

The visualization presented here intentionally condenses this shift in a conceptual manner. It does not depict a specific product, but rather an idea: flying AI as an active agent within industrial systems. The focus is not on technical precision, but on the interaction between autonomy, physical work, and safe distance from human operators. The drone is shown not as a tool, but as part of a distributed, intelligent system.

At this point, a fundamental shift becomes visible. Industrial work is no longer organized exclusively around the human body, but around safety, scalability, and system intelligence. Autonomous drones mark the transition from isolated deployments to continuous, machine driven operations in demanding environments.

What Flying AI Enables in Industrial Contexts

Industrial robotics has been established for many years. Stationary systems and automated machines perform precise tasks in clearly defined environments. Flying AI with autonomous drones extends this landscape with an additional capability: flexible access to work locations that are difficult or costly to reach with ground based systems.

By combining flight capability, mechanical functions, and AI driven control, systems emerge that not only inspect but actively work on industrial infrastructure. Drones stabilize themselves on lines, move along existing networks, and perform tasks that previously required manual labor, specialized vehicles, or temporary shutdowns. This opens up new operational possibilities, particularly for large scale or exposed installations.

Autonomous drone in operation: Flying AI enables work on hard to reach infrastructure

Visualization: © Ulrich Buckenlei | Conceptual depiction of autonomous drones in industrial environments | No claim of technical accuracy

Industrial value does not result from a single technical feature, but from the interaction of multiple components. Mobility, mechanical capability, energy supply, and control systems work together to form a functional work platform. Flying AI does not fully replace existing methods, but expands them with new spatial and operational options.

- Extended reach → Operations in exposed or hard to access locations

- Direct execution → Physical tasks instead of pure data capture

- System integration → Embedded in existing industrial processes

This interaction forms the technical foundation for the industrial use of flying AI. The next chapter therefore focuses on how these systems perform physical work, absorb forces, and maintain stability while moving along existing infrastructure.

When Flying Systems Perform Physical Work

Flight alone does not turn a drone into an industrial work device. The decisive factor is the ability to physically interact with the environment. In industrial applications, this means absorbing forces, establishing stability, and executing controlled movements along existing structures. Only then does a flying system become a functional work platform.

Autonomous drones designed for industrial use deliberately stabilize themselves on lines, beams, or structures. These contact points are used not only for positioning, but also for energy transfer, movement, and precise task execution. Work does not take place in free flight, but in controlled contact with the object. Mechanics, sensors, and control systems interact to enable safe and repeatable processes.

Drone performing physical work: Top view of stabilization and controlled movement along a line

Visualization: © Ulrich Buckenlei | Conceptual depiction of autonomous drone systems | No claim of technical accuracy

This mode of operation fundamentally differs from classic inspection drones. Instead of merely collecting data, the systems directly act on the infrastructure. Movements follow clearly defined paths, forces are continuously measured, and adjustments are made in real time. Tasks can thus be reliably repeated without manual planning or constant supervision.

- Stabilization → Physical contact replaces free hovering

- Force absorption → Mechanical loads are controlled and dissipated

- Guided movement → Tasks are performed along existing structures

Chapter two demonstrates why flying AI should not be seen as an extension of traditional drones, but as an independent form of industrial work. The next chapter focuses on how energy supply, continuous operation, and reliability qualify these systems for long term deployment.

From Individual Flights to Systemic Autonomy

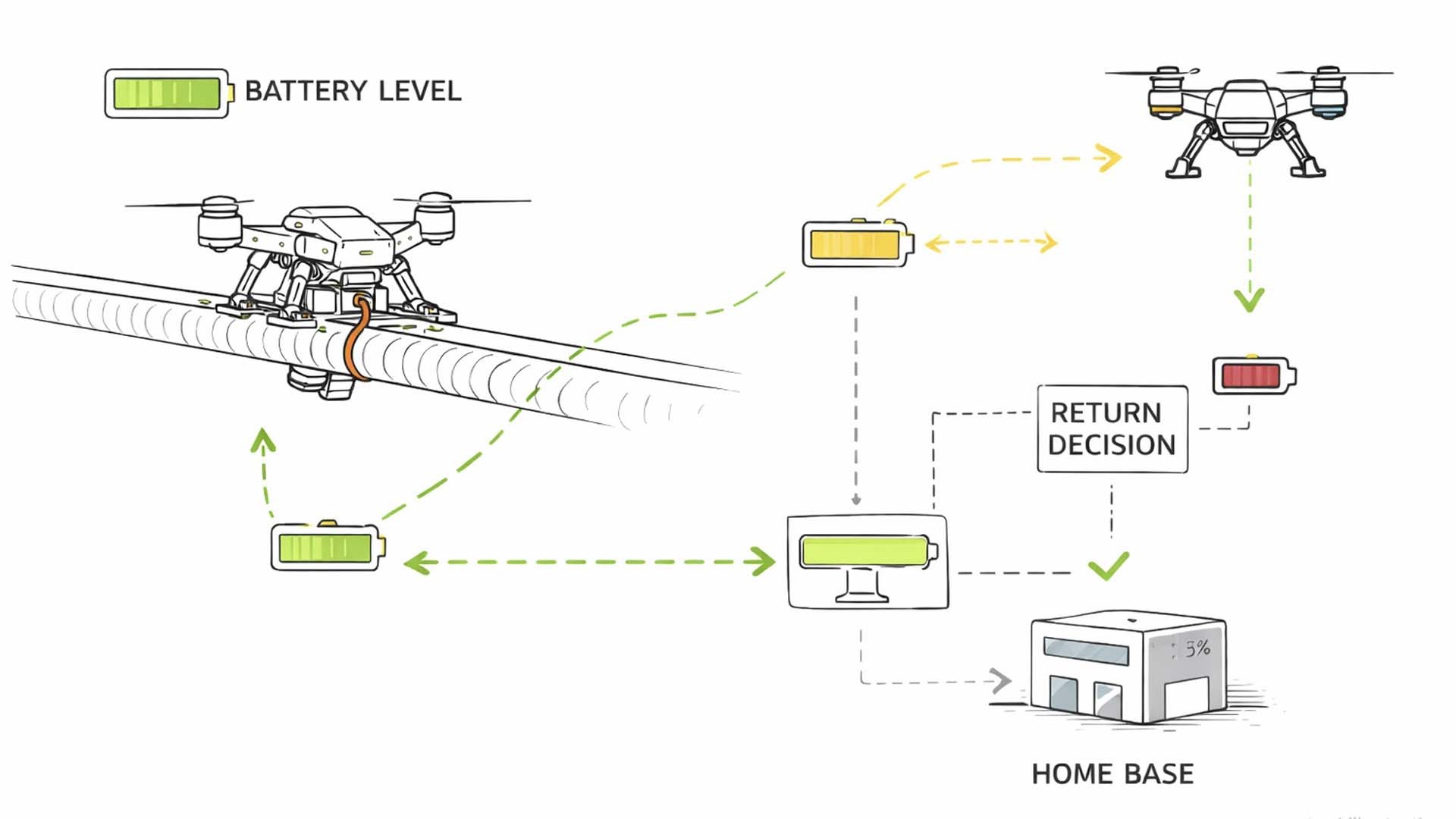

At this stage, the perspective shifts from the individual drone to the overall system in which it operates. Flying AI in industrial use does not function as an isolated device, but as part of a continuously controlled technical framework. What matters is not the individual mission, but the ability to detect states, derive decisions, and adapt behavior accordingly.

Autonomy here does not mean total independence, but controlled self regulation. The drone continuously evaluates parameters such as energy status, position, task context, and environmental conditions. Decisions are not pre programmed in detail, but made within clearly defined system boundaries. The image shifts from tool to operational entity.

Conceptual visualization of autonomous drone logic: Energy state, mission decisions, and feedback as part of a continuous system

Visualization: © Ulrich Buckenlei | Conceptual depiction of autonomous drones in industrial environments | No claim of technical accuracy

Energy management makes this system character particularly visible. The key question is not whether a drone can fly, but how long, how far, and under which conditions. Charge levels, return decisions, or holding positions are part of continuous evaluation. Work is not interrupted, but modulated. The system organizes itself within predefined safety and decision frameworks.

- Systemic autonomy → Decisions emerge from state evaluation, not single commands

- Energy as control variable → Charge level influences mission behavior and return

- Controlled self regulation → Autonomy within clearly defined limits

This chapter highlights that flying AI in industrial environments succeeds not through spectacular actions, but through reliable system logic. The next chapter focuses on how this autonomy remains connected to human oversight and why human in the loop plays a central role.

Human in the Loop: Control Remains with People

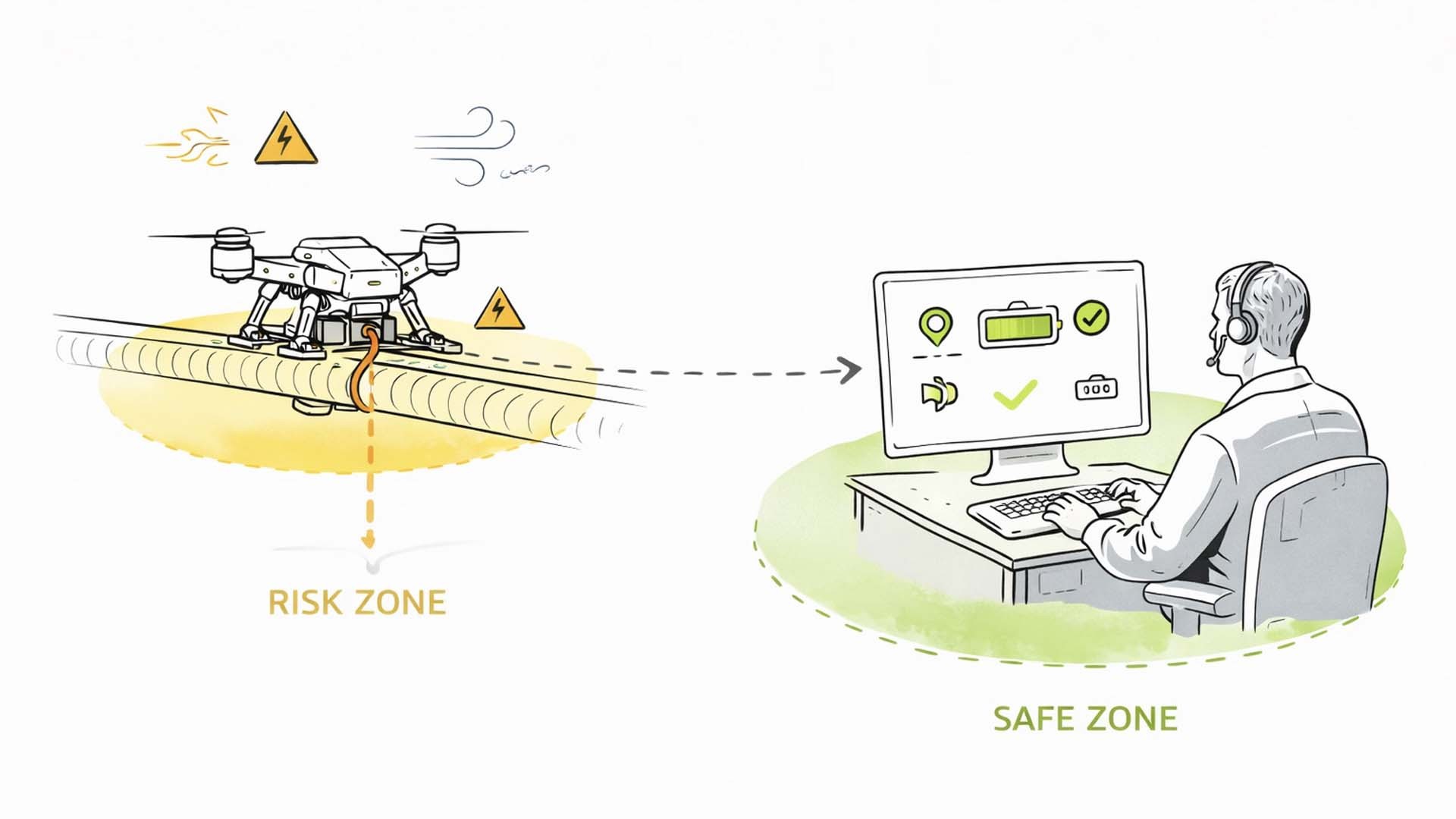

As industrial AI systems become more autonomous, the focus shifts from execution to oversight. Autonomous flying drones operate independently in physical space, but their decisions are not isolated. They are embedded in clear monitoring, approval, and escalation structures that ensure human responsibility.

Operational intelligence does not reside solely in the drone, but in the interaction between sensors, mission logic, and external control. Humans define operational boundaries, monitor system states, and intervene when necessary. Autonomy here does not mean loss of control, but a deliberate shift from physical presence to strategic supervision.

Human in the loop control: Autonomous systems act independently while remaining continuously monitored and controllable

Visualization: © Ulrich Buckenlei | Conceptual illustration | No claim of technical accuracy

This structure is critical for industrial use. Autonomous systems take on dangerous or hard to reach tasks without transferring responsibility. Humans remain part of the decision chain, not as operators of individual movements, but as authorities for assessment, approval, and intervention.

In critical infrastructure, the value of this approach becomes particularly clear. Safety does not result from maximum autonomy, but from clearly defined control points, transparent system states, and the ability for human intervention.

- Remote supervision → Control from a safe distance

- Escalation logic → Human intervention in edge cases

- Responsibility preserved → Autonomy does not replace oversight

This makes it clear that modern industrial AI does not aim for full independence. Its goal is a resilient interaction between machine execution and human control. This balance forms the basis for the next step: designing systems that are safe, scalable, and ethically responsible over the long term.

Safety as a Design Principle, Not a Constraint

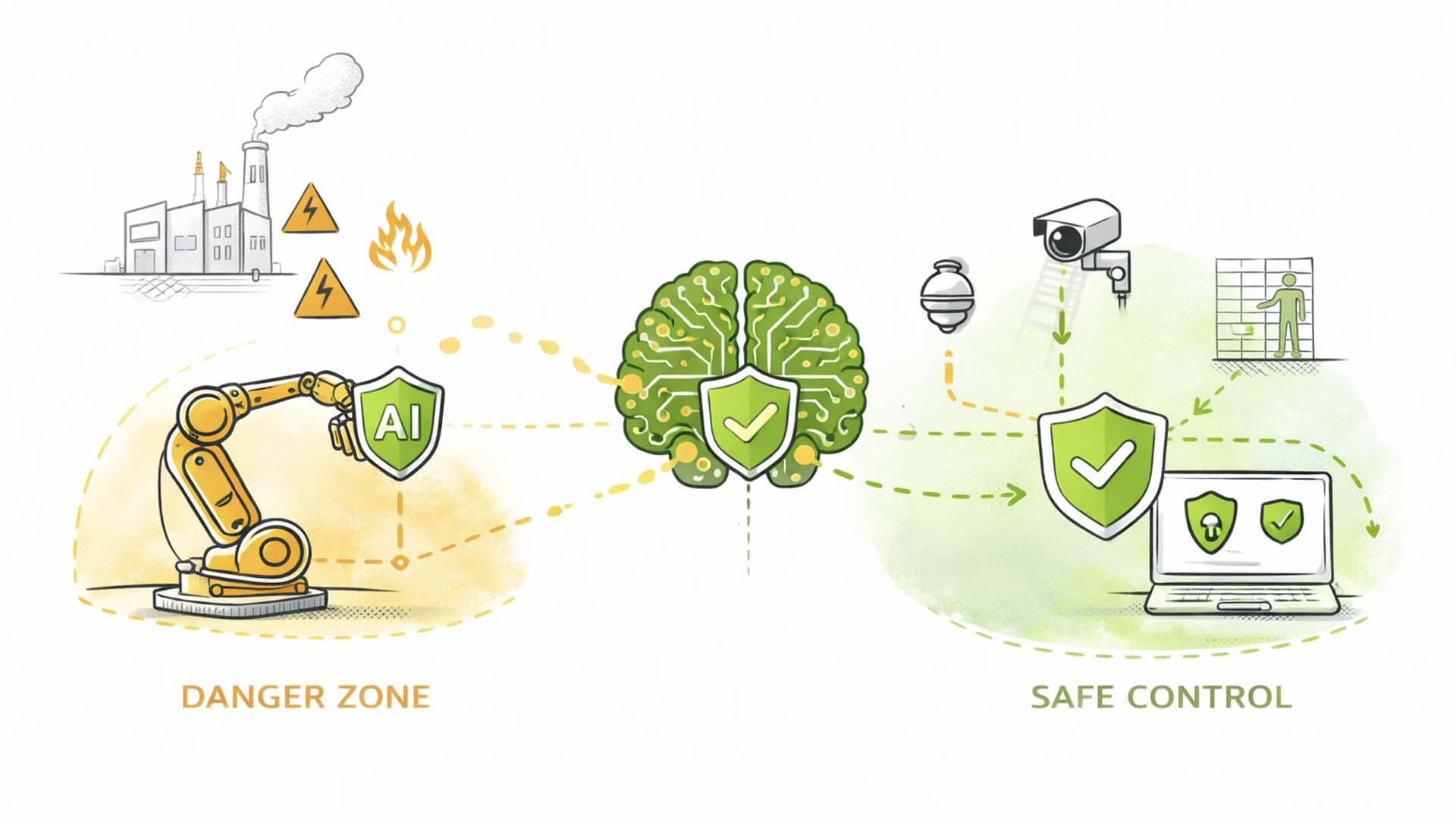

The focus now shifts from spatial separation to the role of artificial intelligence itself. Safety is no longer achieved through isolation or rigid rules, but through continuous evaluation. AI analyzes states, detects deviations, and assesses risks in real time, long before they become visible or perceptible to humans.

AI does not act as an independent agent, but as an intermediary between physical reality and human oversight. Sensor data, system states, and contextual information are combined to form the basis for decisions that remain transparent and verifiable. Safety is not managed after the fact, but designed into the system.

Artificial intelligence as a safety layer: State analysis, decision logic, and human oversight in interaction

Illustration: Conceptual depiction | No claim of technical validation

This logic fundamentally changes the understanding of industrial responsibility. Humans remain part of the decision chain, but intervene where evaluation, control, and supervision are meaningful, not where physical danger arises. Designing safe systems therefore begins not at the edge of the process, but in its architecture.

- AI as evaluation layer → Safety through continuous analysis

- Human oversight → Decisions remain transparent and reviewable

- Design over reaction → Safety is embedded systemically

This chapter marks the transition from spatial separation to intelligent control. The next section focuses on how such systems can be operationally integrated into industrial workflows and the role of autonomous processes and infrastructure.

Autonomy Emerges Through System Interaction

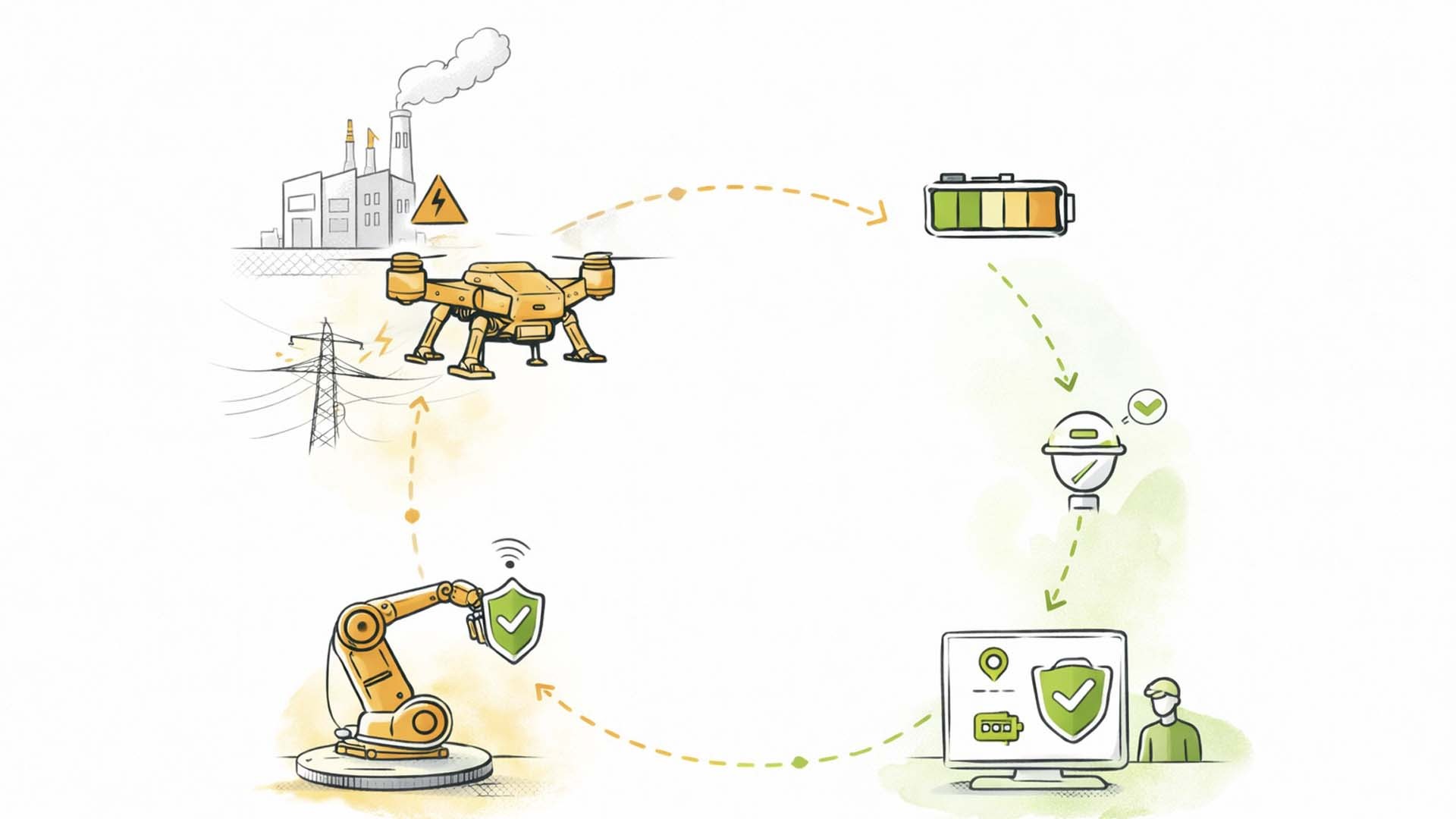

The perspective now shifts from the individual machine to the overall system. Autonomous drones achieve impact not in isolation, but as part of a distributed technical infrastructure. Sensors, navigation, energy management, and decision logic interact to enable continuous operation in complex industrial environments.

The systems shown illustrate that autonomy does not mean acting without oversight. Robust processes emerge through clearly defined transitions between automated execution, state monitoring, and human control. The drone operates independently within defined parameters, while remaining embedded in a higher level system.

- Distributed intelligence → Autonomy emerges from multiple interacting subsystems

- Continuous operation → Energy, navigation, and task control work together

- Clear responsibilities → Automation with defined intervention points

Autonomous drones as part of a distributed system: Navigation, energy state, and mission logic are continuously coordinated

Illustration: © Ulrich Buckenlei | Conceptual depiction | No claim of technical accuracy

This systemic perspective distinguishes modern industrial AI from earlier automation approaches. The focus is not on individual functions, but on the interaction of data, states, and decisions. Autonomy becomes a question of architecture and process design, not of maximum independence.

Video: Physical AI in Industrial Use Under Real Conditions

The following video shows autonomous drones operating on critical infrastructure. The focus is not on a single device, but on the interaction between perception, targeted physical interaction with the environment, and safe distance from humans. This is where Physical AI becomes tangible, particularly in weather dependent, hard to access, or high risk work scenarios.

The sequences illustrate what can remain abstract in text. These systems operate under physical constraints, respond to resistance, stabilize themselves in motion, and perform tasks that previously involved significant risk. Industrial work gradually shifts from on site presence to supervised execution.

Video still as a conceptual illustration in XR Stager style, visualization without claim of technical accuracy

Video material from publicly available industrial footage, rights remain with respective owners, editorial analysis and context by Ulrich Buckenlei

Note: The video is included for journalistic and analytical purposes and is optimized for mobile playback, including iOS

The footage shows that Physical AI is not a distant vision, but already being tested and deployed in high risk industrial contexts. The decisive factor is a new operational logic. Autonomy does not mean unrestricted action, but controlled execution within clear rules, transparency, and responsibility.

- Embodied autonomy → Systems respond to real resistance and material behavior

- Energy autonomy → Charging, pausing, and resuming become part of mission logic

- Safety by design → Work shifts from danger zones to controlled oversight

When Autonomous Systems Become Industrial Reality

The use of autonomous flying AI in industrial environments demonstrates that digital systems no longer merely analyze or visualize. They actively intervene in physical processes, perform tasks under real world conditions, and shift work from hazardous zones into controllable structures. What matters is not the individual drone, but the interaction between perception, autonomy, energy management, and human oversight.

This is precisely where the Visoric expert team based in Munich operates. The focus lies on translating complex technical systems into clear models, visual structures, and understandable decision logic. Whether Physical AI, autonomous systems, or industrial real time processes, the goal is not just to show technology, but to contextualize it, explain it, and make it strategically usable.

The VISORIC expert team: Ulrich Buckenlei and Nataliya Daniltseva discussing autonomous systems, industrial AI, and the translation of complex technologies into understandable models

Source: VISORIC GmbH | Munich

Visoric combines analysis, system understanding, and visual communication. The objective is not staging for its own sake, but clarity. How do autonomous systems function at industrial scale. Where are the operational opportunities and limits. And how can safety, control, and efficiency be embedded as design principles from the outset.

- Analytical classification of autonomous and AI driven industrial systems

- Conceptual design of visual models for complex technical relationships

- Translation of system logic into clear narratives for decision makers

- Design of visualizations, simulations, and explanatory formats

- Connecting industrial reality, AI, and strategic communication

The article demonstrates that Physical AI is not a promise of the future, but an operational development. Those involved in the introduction, evaluation, or communication of autonomous systems will find a grounded, objective, and practice oriented perspective for the next steps through exchange with the Visoric expert team.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich