Image credit: BMW Group / NVIDIA – Fair Use for Educational Purposes

The BMW Group is redefining the way vehicles are developed by integrating next-generation simulation environments into its core R&D processes. Instead of relying solely on physical wind tunnels or mechanical test benches, BMW is now deploying sophisticated neural networks and AI-powered digital twins that can simulate aerodynamic behavior, energy flows, and performance parameters with exceptional precision. These virtual systems do not merely replicate the physical world – they enhance it, enabling engineers to explore a vastly expanded design space, optimize in real time, and iterate far beyond what traditional prototyping ever allowed.

Through strategic collaboration with Siemens and NVIDIA, BMW is embedding these simulation capabilities into a broader digital ecosystem that connects physics-based modeling with real-time data analytics and GPU-accelerated computing. Siemens provides the industrial backbone through intelligent factory orchestration and simulation platforms, while NVIDIA supplies the computational power and AI frameworks needed to process complex data models at scale. Together, these technologies create a seamless feedback loop between design, testing, and production – a dynamic, intelligent environment where innovation is no longer bound by physical constraints, but fueled by computational foresight.

From Physical Tunnels to Neural Networks

For many decades, traditional wind tunnel technology served as the gold standard for evaluating and refining vehicle aerodynamics. These massive physical installations allowed engineers to observe how air moved around a car’s body and make incremental adjustments to improve drag coefficients and performance. While effective, the process was inherently linear, time-intensive, and limited in scope. Only a finite number of scenarios could be tested, and real-time responsiveness was virtually nonexistent.

Today, the BMW Group is leaving these limitations behind. By leveraging AI-driven data models and high-fidelity real-time simulation environments, the company is transforming aerodynamic analysis into a predictive, adaptive process. Airflow behavior can now be not only visualized in minute detail but also dynamically influenced during the design phase. Instead of reacting to test results, BMW engineers proactively shape aerodynamic outcomes, using intelligent systems that learn from vast datasets and continuously optimize for efficiency, stability, and performance – long before a physical prototype even exists.

- Neural networks interpret aerodynamic influences in real time

- Digital twins replace complex physical testing setups

- Simulations are visualized within NVIDIA Omniverse

XR-enhanced aerodynamics visual inspection

Illustration: Visoric GmbH

The integration of simulation-driven development fundamentally accelerates the innovation cycle. What once required multiple physical iterations and extensive testing now unfolds in a virtual environment with unprecedented speed. This shift allows engineers to detect potential aerodynamic issues earlier, iterate faster, and make data-informed design decisions before any physical prototype is built.

As a result, aerodynamic efficiency is no longer an outcome of late-stage refinement, but a core parameter of the initial design phase. By embedding intelligence into the earliest stages of development, the BMW Group ensures that each design iteration is both faster and functionally superior. This not only reduces time-to-market but also leads to vehicles that are aerodynamically optimized from the very first sketch.

New Aerodynamics with AI

Artificial intelligence is turning aerodynamics development into a dynamic, adaptive process. Instead of relying on static models or sequential testing stages, engineers now work within responsive systems that adjust in real time. These systems continuously learn from high-fidelity simulations, enabling them to predict how airflow interacts with various shapes and surfaces across countless conditions.

This real-time responsiveness unlocks a new level of precision. Engineers can fine-tune every curve and component digitally, long before physical prototypes are created. By leveraging machine learning, the BMW Group gains the ability to explore more design variations in less time—resulting in smarter material choices, optimized structures, and ultimately more efficient vehicles from the ground up.

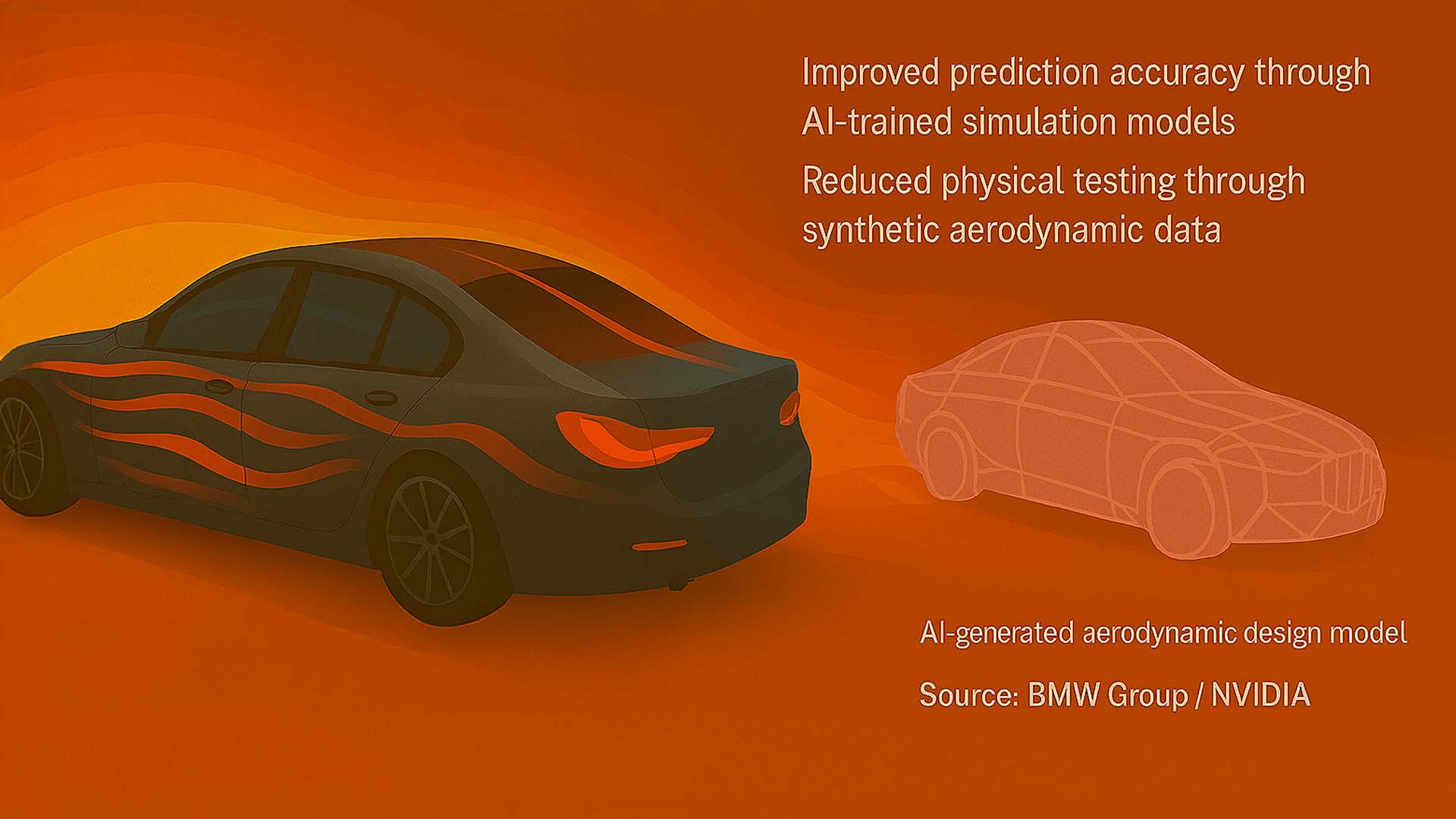

- Improved prediction accuracy through AI-trained simulation models

- Reduced physical testing through synthetic aerodynamic data

- Real-time shape adaptation via generative design algorithms

AI-generated aerodynamic design model

Illustration: Visoric GmbH

Through training on extensive simulation datasets and decades of wind tunnel benchmarks, AI systems are now able to generate novel aerodynamic forms that go far beyond traditional engineering intuition. These machine-generated designs often reveal performance potentials that would remain hidden in conventional workflows, unlocking new possibilities for efficiency and innovation.

For automotive leaders like the BMW Group, this means reimagining the design process itself. Instead of iterating around past solutions, engineers can explore fundamentally new geometries proposed by AI, dramatically accelerating development timelines while achieving superior aerodynamic performance from the earliest design phases.

From Wind Tunnel to Neural Net

While traditional wind tunnels still play a vital role in vehicle development, their function is evolving rapidly. Today, they operate not as isolated testing tools, but as integral components of a larger AI-enhanced feedback loop. Neural networks trained on wind tunnel output are capable of detecting aerodynamic patterns and anomalies invisible to human engineers—transforming raw measurements into predictive insights.

This synergy between physical testing and machine learning amplifies the value of each data point. Instead of simply validating designs, wind tunnel sessions now serve as training environments for intelligent systems. As a result, every test becomes a data-rich event that feeds back into AI models, enabling continuous optimization and unlocking new levels of aerodynamic efficiency and design intelligence.

- Neural nets enhance tunnel data with predictive capabilities

- Physical and digital aerodynamics merge in hybrid systems

- Realtime adjustments during tunnel sessions powered by AI

Hybrid wind tunnel with AI-driven feedback

Illustration: Visoric GmbH

The convergence of AI and wind tunnel technology has redefined how innovation unfolds in automotive design. Engineers are no longer limited to verifying preexisting concepts, they now test and refine both human-developed and AI-generated shapes in parallel. This dual-track approach enables rapid comparisons, instant feedback, and continuous iteration within a single simulation loop.

By integrating this real-time capability into aerodynamic workflows, the wind tunnel becomes more than a physical lab—it evolves into an adaptive AI system. Each test refines the model, and each model informs the next design. The result is a dynamic, data-driven environment where design decisions are no longer reactive but anticipatory, shaped by the intelligent interplay between human creativity and machine-accelerated insight.

The Role of Synthetic Data

AI-generated synthetic aerodynamic data is pushing the boundaries of what’s possible in virtual vehicle design. Instead of relying solely on real-world testing or conventional simulation tools, engineers can now explore thousands of complex airflow scenarios using advanced techniques like Gaussian splatting and procedural flow fields. These methods allow for high-resolution, physics-aware representations of turbulence, pressure zones, and micro-interactions with a level of granularity far beyond traditional models.

This virtually unlimited simulation power opens new creative and technical frontiers. Designs that would once be considered too experimental, too costly, or too risky to test physically can now be explored safely and efficiently in digital space. It enables a more radical approach to form-finding, where performance is optimized not just through incremental improvements, but through exploratory leaps guided by machine intelligence.

- Procedural data generation expands training datasets

- Enables virtual testing of edge-case aerodynamic events

- Supports real-time training of design algorithms

Immersive aerodynamic simulation in XR cockpit — from automotive to aerospace

Illustration: Visoric GmbH

The reach of AI-enhanced aerodynamic simulation extends far beyond the automotive world. Engineers are now applying these powerful synthetic environments to fields like aerospace, drone development, and even high-performance sports equipment. By tailoring simulations to the specific physics of each use case, these environments replicate real-world conditions with remarkable accuracy—whether it’s airflow around a racing bike or pressure zones on an aircraft wing during takeoff.

This cross-industry application is transforming how products are designed and optimized. With AI generating millions of data points, teams can analyze shape performance, material behavior, and aerodynamic response in ultra-fine detail before a single physical test is conducted. The result is faster innovation, reduced costs, and smarter designs across multiple sectors—all powered by adaptive, AI-driven simulation ecosystems.

Generative Engineering for Performance

Generative design introduces a paradigm shift in aerodynamic engineering. By integrating AI directly into the design process, engineers no longer start from a single concept to optimize manually. Instead, they define boundary conditions—such as weight distribution, material properties, structural constraints, and drag coefficients—and let AI systems autonomously generate a broad spectrum of high-performance shapes that fulfill these parameters. Each design variation is tested virtually for aerodynamic viability, efficiency, and manufacturability, often revealing unexpected geometries that outperform traditional concepts.

This evolution empowers teams to move from intuition-driven design to data-driven exploration. Rather than being limited by human preconceptions, engineers receive dozens or even hundreds of AI-generated proposals, each representing a different path through the multidimensional space of possibilities. These outcomes are not only highly optimized but also inspire creative breakthroughs by visualizing aerodynamic solutions that would be difficult to conceive manually.

- Massive parallel exploration of design permutations

- AI filters out non-viable aerodynamic concepts

- Designers focus on selecting, not guessing

AI-generated aerodynamic geometry for automotive use

Illustration: Visoric GmbH

The integration of AI into the design process marks a fundamental change in engineering philosophy. Instead of pursuing a single optimal solution through step-by-step iteration, development now becomes an open-ended exploration guided by evolutionary intelligence. Algorithms generate design variants not by following fixed rules, but by adapting and learning from performance feedback across many dimensions. This shift breaks away from deterministic logic and allows for the emergence of forms and structures that may seem counterintuitive but prove superior in real-world conditions.

As a result, innovation becomes less constrained by past experience and more driven by discovery. Engineers are no longer refining known solutions—they are collaborating with intelligent systems that uncover novel aerodynamic configurations through simulation, learning, and self-optimization. These unconventional outcomes often challenge established norms, revealing the untapped potential of designs that were previously unimaginable under traditional engineering paradigms.

Visual Feedback and XR Integration

Extended Reality (XR) is redefining how engineers perceive and interact with aerodynamic data. By visualizing real-time simulations in immersive environments, airflow and drag are no longer abstract values—they become spatial experiences. Whether through Mixed Reality headsets or AR overlays on tablets, engineers can now step directly into dynamic airflow fields, observe turbulence zones at full scale, and intuitively grasp how air behaves around specific geometries. This spatial immersion enhances understanding far beyond what flat screens or static charts can offer.

The ability to “walk through” a simulation enables new forms of collaboration and creativity. Teams can explore how subtle shape changes affect drag, pressure, or vortex formation with immediate visual feedback. These environments support shared decision-making and rapid iteration in a way that traditional CAD tools or charts simply can’t match. By bridging the gap between complex data and human perception, XR becomes an active partner in aerodynamic design—turning invisible forces into tangible insights.

- AR overlays show live feedback on design prototypes

- MR headsets allow intuitive spatial inspection of flow fields

- Enhances collaborative engineering across remote teams

XR-enhanced aerodynamics visual inspection

Illustration: Visoric GmbH

Extended Reality is not just a visualization tool—it’s becoming a core driver of collaborative aerodynamic engineering. When global teams operate across time zones and disciplines, XR provides a shared, real-time environment where everyone can engage with the same simulation, geometry, and data. Engineers in Munich, Tokyo, or California can enter the same airflow scenario, observe the same pressure zones, and align design decisions instantly. This eliminates communication barriers and dramatically shortens feedback cycles.

At the same time, XR tools allow for unprecedented precision in evaluating and refining aerodynamic features. Design teams can interact with micro-level geometry details, test modifications live, and immediately assess how changes influence airflow and drag. This high-resolution responsiveness turns each iteration into a dynamic co-creation session—blending data-driven decision-making with spatial intuition. The result: faster breakthroughs, higher design fidelity, and truly global collaboration.

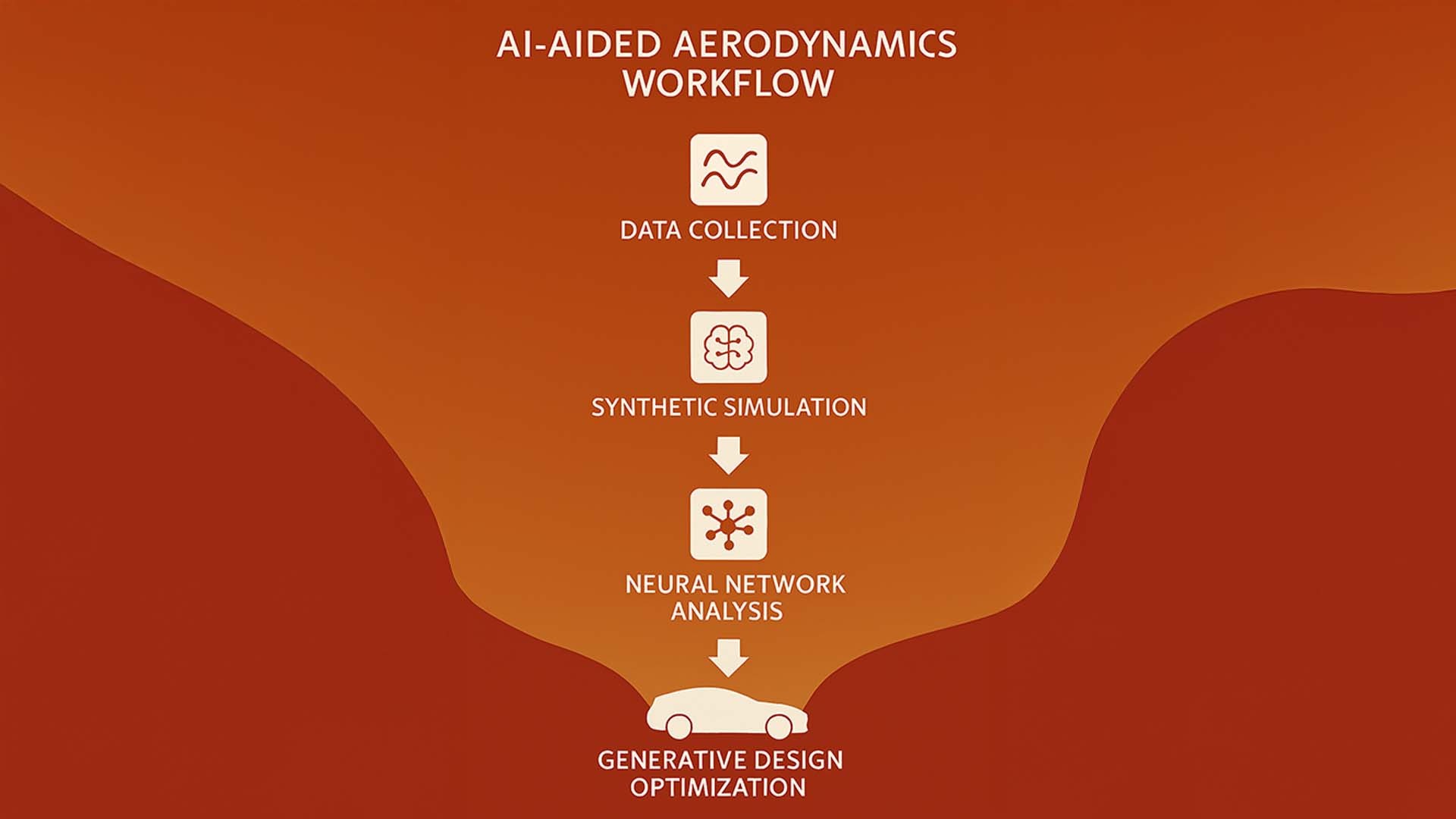

Infographic: AI-Aided Aerodynamics Workflow

This diagram illustrates the complete lifecycle of AI-driven aerodynamic design, beginning with raw data collection from physical sensors and simulations. From there, synthetic data environments replicate airflow behaviors across countless variables, enabling faster and more scalable experimentation. These environments are enriched with real-world measurements, creating a feedback loop that steadily refines model accuracy and predictive power.

At the core of this transformation lie neural networks and generative design algorithms. Once trained on simulation data and performance benchmarks, these systems evolve designs autonomously—exploring structural variations, drag optimizations, and shape efficiencies beyond the reach of traditional methods. What was once a linear, time-consuming process becomes an intelligent, adaptive system that moves toward optimal solutions in real time.

AI-enhanced aerodynamic workflow from data to deployment

Infographic: Visoric GmbH

The infographic breaks down the layered evolution of engineering workflows in the age of AI. It reveals how once-isolated tasks—such as data analysis, simulation, and prototyping—are now connected through intelligent systems that streamline decision-making. Each phase becomes part of a larger, integrated feedback loop, where engineers act more as orchestrators of autonomous processes than manual operators.

This shift empowers teams to move faster and with greater confidence. AI-supported roles blend human creativity with machine precision, allowing for design iterations that adapt dynamically to performance data and evolving requirements. Instead of static development pipelines, companies build responsive systems that learn, optimize, and improve continuously across projects.

Video: Real-Time Aerodynamics Optimization

The video shows a real-time aerodynamic optimization process powered by AI, with live feedback loops and visual performance predictions displayed through XR. It reveals how engineers iterate design and flow control without leaving the virtual lab.

Live optimization in real-time simulation using AI

Source: BMW Group / NVIDIA / XR Stager

This video showcases the future of collaborative aerodynamics—where immersive visualization, autonomous computation, and interactive design tools merge into a seamless engineering environment.

Cut costs, boost performance – get started now

If your organization is looking to accelerate design cycles, reduce testing costs, and unlock new performance frontiers, AI and XR offer a powerful combination. These technologies transform aerodynamic workflows into intelligent, immersive ecosystems—where ideas are validated in real time, and innovation scales beyond physical limitations.

Whether you’re developing vehicles, aircraft, or advanced products requiring precision airflow control, now is the time to explore what AI-driven simulation and extended reality can do for your team. The path to faster, smarter, and more adaptive engineering begins with a conversation.

- Our experts at Visoric specialize in immersive engineering environments

- We support automotive and aerospace clients with AI-driven solutions

- Get in touch for consulting, prototyping, or full-scale implementation

Accelerate your innovation today, connect with the Visoric team for a personalized walkthrough of what’s possible in your domain.

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich