Visoric presents the world’s first Digital Supply Chain Twin

Photo: © Visoric GmbH | Innovations for pioneering supply chain management.

Revolutionary Technology at ALSC 2024 in Munich

At the ALSC Digital Strategies Europe 2024 in Munich, Visoric GmbH, together with Prof. Dr. Tobias Engel and the TTZ Smart Production and Logistics Team, unveiled a groundbreaking innovation: the world’s first Digital Supply Chain Twin. This solution was exclusively showcased on the Apple Vision Pro Spatial Computing Headset, offering a completely new way to visualize, manage, and optimize supply chains.

Presentation of the Digital Supply Chain Twin at ALSC 2024

Photo: © Visoric GmbH | A glimpse into the future of supply chain management.

The Digital Supply Chain Twin combines cutting-edge technologies such as 3D visualization, real-time simulation, and AI-powered data analysis. This interactive solution transforms traditional supply chain management into a dynamic and proactive process. Companies can visualize and optimize every step of their supply chain in real time, from inventory tracking to planning sustainable transport routes.

- Real-time visualization: Analyze global supply chains and accurately display local details.

- Sustainable logistics: Track and optimize CO₂ emissions.

- Efficiency enhancement: Make better decisions with data-driven insights.

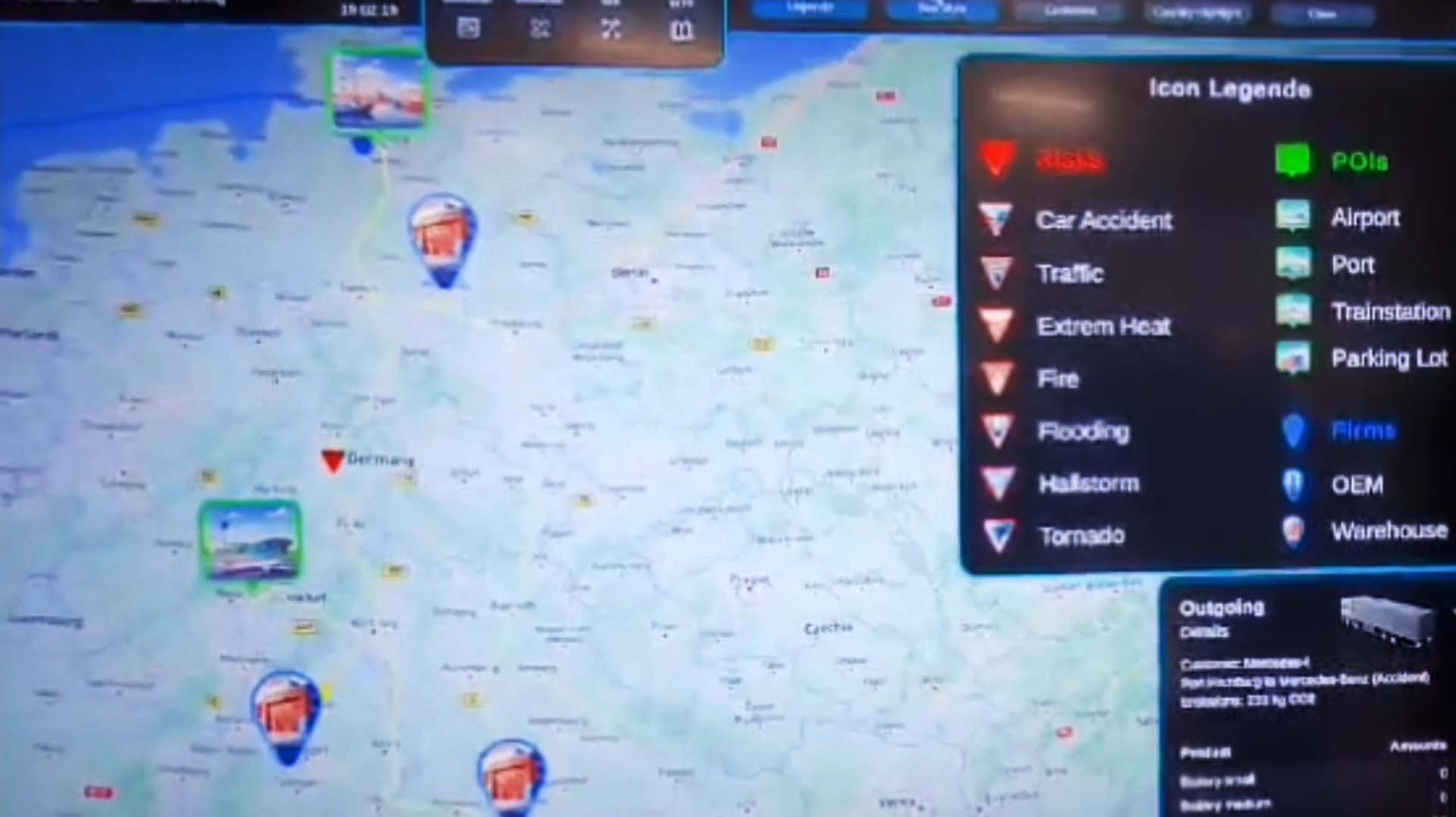

Proactive Risk Management for Stable Processes

A standout feature of the Digital Supply Chain Twin is its ability to proactively identify risks. Whether natural disasters or logistical delays, the system highlights potential disruptions before they become serious issues.

Proactive Risk Management with Digital Twins

Photo: © Visoric GmbH | Identifying and avoiding risks early on.

This technology enables companies to respond flexibly and quickly to unexpected events, such as delays caused by storms or unforeseen shortages. This ensures stable and efficient operations.

- Early warning system: Detect risks in real time.

- Agile decision-making: Quick responses to unexpected events.

- Minimizing disruptions: Ensure continuous processes.

Sustainability in the Supply Chain

Another focus of the system is monitoring and optimizing CO₂ emissions. This helps companies make more environmentally friendly decisions and achieve their climate goals.

Sustainability through CO₂ tracking

Photo: © Visoric GmbH | Designing more environmentally friendly supply chains.

The integration of sustainability analytics allows the impact of transportation routes on the environment to be minimized. This is a significant step towards responsible supply chains.

- CO₂ monitoring: Prioritize eco-friendly alternatives.

- Efficient planning: Define optimal transportation routes.

- Sustainable innovation: Achieve climate goals efficiently.

Experience Innovations in Video

The following video demonstrates how the Digital Supply Chain Twin works in action. Presented at ALSC 2024, it offers impressive insights into the future of supply chain management.

Video: © Visoric GmbH | Live demonstration at ALSC 2024 in Munich.

Contact Us for Your Digital Transformation

Visoric supports companies in implementing state-of-the-art technologies such as digital twins, AI, and real-time simulations. Our tailor-made solutions help you optimize your processes and become more sustainable.

- Consulting: Solutions tailored precisely to your requirements.

- Implementation: Seamless integration of innovative technologies.

- Sustainable strategies: Make processes more efficient and eco-friendly.

Contact Us:

- Phone: +49 89 2155 2678

- Website: visoric.com

- Email: info@visoric.com

Visoric looks forward to shaping the future of your supply chain together!

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobile: +49 152 53532871

Email: ulrich.buckenlei@visoric.com

Nataliya Daniltseva (Project Manager)

Mobile: +49 176 72805705

Email: nataliya.daniltseva@visoric.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich